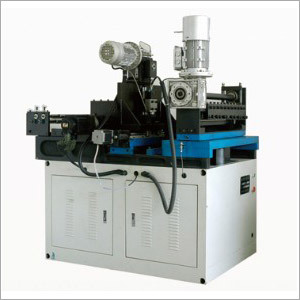

Swing Shear and Punching Machine

Product Details:

10000.00 - 100000.00 USD ($)/Set

X

Swing Shear and Punching Machine Price And Quantity

- 10000.00 - 100000.00 USD ($)/Set

- 1 Millimeter

Swing Shear and Punching Machine Trade Information

- 10 Millimeter Per Month

- 60 Days

Product Description

We have earned a remarkable position in Cangzhou, Chian as a trusted manufacturer and exporter of technically superior range of NC Swing Shear & Punching Machine. We use the most modern production technology and excellent grade raw materials and components to ensure high durability and performance reliability. This type of machine is used for shearing and punching of various types of metal including copper, aluminium, carbon steel, stainless steel, alloy, etc. NC Swing Shear & Punching Machine is an automatic model with colors can be supplied as per the choice of the clients.Features:

- Impeccable quality

- Superlative finishing

- Fully automatic operating system

- Economical

Model:HJ-3003/4003/5003/8003B

Introduction and Usage

- This machine is mainly used for both straight&mitred cutting

- silicon steel laminations for transformer or reactors automatically.

- Cut the sillicon steel to be kinds of shape,such as right angle,bevel angle,

- Straight angle& bevel angle, hole punched,V -notch etc.

- This machine also has step-lap function.

Specification

- Cutting length:200-5000mm

- Cut-to-length precision:+-0.02mm

- Cutting angle precision:Max 0.025degrees

- Cutting burr height:Max0.02mm

- Punching burr height:Max0.03mm

- Cutting speed:25-50 pieces per minute

- Cutting power: Support the inverter motors of domestic famed brands, incorporate advanced speed, cut down the noise, extended service life.

- Feeding power: Appoint big torque AC servo motors, fast response, high and valuable positioning, low tumult, small thermal decline, durable life.

- Rail positioning: Step motor drings, central locations, ball screws & linear guide consignment, speedy and precious.

- Motion control: The motion control is executed by advanced PLC, HMI (Human Machine Interface) operation, effortless, convenient and adaptable maintenance.

- Lamination collecting: Circulating bells plus unloaded racks.

- Life assurance: The imported and worlds' most popular linear guides, ball screws, highly precious milling components are provided, advanced and precised assembly, enhanced service lives of the machines.

Enter Buying Requirement Details