Transformer Vertical Coil Winding Machine

Price 10000 USD ($)/ Unit

Transformer Vertical Coil Winding Machine Specification

- Product Type

- Coil Winding Machine

- General Use

- Transformer Coil Winding

- Material

- Mild Steel

- Type

- Vertical Winding Machine

- Weight (kg)

- Approx. 1200 kg

- Computerized

- Yes

- Automatic

- Automatic

- Control System

- PLC Controlled

- Power Source

- Electric

- Power Consumption

- 5 kW

- Coil Diameter

- 300 mm - 1200 mm

- Winding Head

- Single Head

- Winding Speed

- 0-120 rpm (Adjustable)

- Winding Spindle

- Vertical Spindle

- Air Pressure

- 0.6-0.8 MPa

- Drive Type

- Servo Motor Driven

- Voltage

- 380V/415V, 3 Phase

- Dimension (L*W*H)

- 2600*1400*1850 mm

- Feature

- High Precision, Easy Operation, Digital Counter

- Color

- Blue & White

- Minimum Winding Wire Diameter

- 0.2 mm

- Noise Level

- <70 dB

- Application

- Used for Manufacturing Power and Distribution Transformer Coils

- Display Interface

- Touchscreen HMI

- Tension Control

- Automatic Tension System

- Operating Temperature

- 0°C - 50°C

- Maximum Winding Wire Diameter

- 5 mm

- Max. Coil Width

- 300 mm

- Safety Feature

- Emergency Stop, Overload Protection

Transformer Vertical Coil Winding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Transformer Vertical Coil Winding Machine

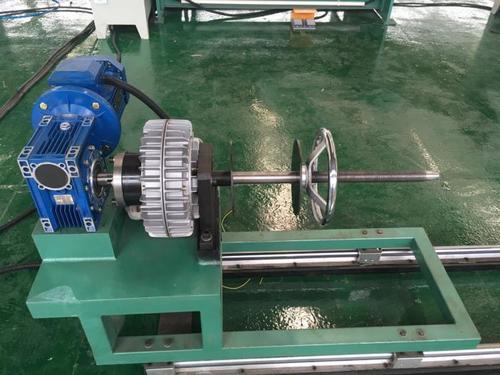

Transformer Vertical Coil Winding Machine

Transformer Vertical winding machine has 10t, 15t, 20t, 25t, 30t, 35t and other models, disk diameter and lift the trip can be designed according to user requirements, according to user requirements to provide the corresponding auxiliary.

Advanced Automation for Precision Winding

This machine incorporates a PLC-controlled automatic tension system and servo motor drive to deliver consistent, accurate coil winding every time. The adjustable speed and digital counter enhance operator control, while the touchscreen interface streamlines setup and monitoring. Its automated functions reduce manual intervention, improving efficiency and repeatability in transformer coil production.

Safety and Operator Comfort Focused

Featuring overload protection and an emergency stop function, the machine prioritizes operator safety during high-speed operations. Its low operational noise (<70 dB) and ergonomic design make it suitable for extended use in busy manufacturing environments, while the clear HMI display facilitates convenient supervision and adjustment.

FAQs of Transformer Vertical Coil Winding Machine:

Q: How does the automatic tension system improve the winding process?

A: The automatic tension system ensures consistent wire tension throughout the winding process, which enhances coil precision and reduces the risk of wire breakage or irregular winding. This contributes to higher quality transformer coils and minimizes material waste.Q: What types and sizes of transformer coils can be produced with this machine?

A: The machine is capable of manufacturing power and distribution transformer coils with coil diameters ranging from 300 mm to 1200 mm and widths up to 300 mm, accommodating winding wire diameters between 0.2 mm and 5 mm.Q: When should the emergency stop function be used during operation?

A: The emergency stop function should be activated immediately if there is any perceived risk to operator safety, machine malfunction, or unexpected situations such as wire entanglement, to halt the machine safely and prevent damage.Q: Where can this machine be installed and operated?

A: This winding machine is suitable for installation in industrial manufacturing settings, such as transformer production plants or electrical component factories, provided the environment meets its operating temperature (0C50C) and air pressure (0.60.8 MPa) requirements.Q: What are the advantages of using a servo motor-driven vertical winding machine?

A: A servo motor-driven system offers precise and smooth control over winding speed and positioning, resulting in highly accurate coil geometry, increased productivity, and adaptability for various coil specifications.Q: How can operators monitor and control machine settings?

A: Operators control and monitor machine settings through the touchscreen HMI, which provides real-time data, adjustable parameters, and error alerts, making operation intuitive and easy to manage.Q: What are the main benefits of using this coil winding machine in transformer manufacturing?

A: The main benefits include high winding precision, automated tension control, easy operation, enhanced safety features, lower noise emissions, and versatile adaptability for different coil sizes, leading to improved product quality and production efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

Horizontal Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Heavy Duty Construction, User Friendly Interface, Precise Layer Winding

Coil Diameter : Up to 1200 mm

Computerized : Yes

Power Consumption : 712 kW (depending on configuration)

Automatic 3D Triangle Wound Core Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Energy Efficient, High Precision Winding, UserFriendly Operation

Coil Diameter : 50 300 mm

Computerized : Yes

Power Consumption : 57 kW

Double Layer Low Voltage Foil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Precision, Stable Performance, UserFriendly Operation

Coil Diameter : Max. 1200 mm

Computerized : Yes

Power Consumption : About 7 kW

High Voltage Automatic Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Precision, Programmable, Stable Performance

Coil Diameter : Max 350 mm

Computerized : Yes

Power Consumption : 2.5 kW

Send Inquiry

Send Inquiry