Epoxy Resin Casting Molds For Dry Type Transformer Use

Price 10000 USD ($)/ Unit

Epoxy Resin Casting Molds For Dry Type Transformer Use Specification

- Heating Method

- Electric Heating Plate or Hot Air Circulation

- Power Source

- Electrical

- Control Mode

- Automatic Digital Temperature Controller

- Heating Capacity

- Up to 1500C

- Accuracy

- 1C

- Condition

- New

- Type

- Epoxy Resin Casting Mold

- Model

- ERCMDT-2024

- Internal Size

- Available in various sizes to fit transformer windings

- External Size

- Customizable as per transformer core dimensions

- Volume

- Tailored to dry type transformer requirements

- Air Flow

- Optional forced air circulation

- Temperature Range

- Room temperature to 150C

- Material

- High-strength steel with epoxy resin coating

- Dimension (L*W*H)

- Custom as per customers mold design

- Power

- 3 kW 10 kW, depending on design

- Voltage

- 220V/380V, 50/60Hz

- Surface Finish

- Polished and anti-stick treated

- Safety Features

- Over-temperature shutoff, leakage protection

- Vacuum Compatibility

- Suitable for vacuum resin casting systems

- Demolding Method

- Mechanical or hydraulic demolding system

- Weight

- Varies according to size and customer requirements

- Color

- Metallic grey or customized upon request

- Core Form Factor

- Available for single phase, three phase, and custom shapes

- Mold Life

- Up to 1000 casting cycles with proper maintenance

- Production Technique

- High-precision CNC machining and surface polishing

- Resin Compatibility

- Epoxy, Polyester, and Polyurethane resins

- Application

- Manufacture of medium and high voltage dry type transformer coils

Epoxy Resin Casting Molds For Dry Type Transformer Use Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

About Epoxy Resin Casting Molds For Dry Type Transformer Use

Purpose of the product: Divided into soft and hard molds, casting mold is used for casting of epoxy dry-type transformer coils and is an essential tool for production of dry-type transformer coils.

Components of the device : The hard mold is composed of outer mold, inner mold, outgoing bar and seal strip.The soft mold is composed of outer mold, inner mold, seal strip, clamping plate and pressing plate.

High Durability and Versatile Compatibility

Built to last, the ERCMDT-2024 casting mold supports up to 1000 cycles under proper upkeep. Its suitable for various resinsincluding epoxy, polyester, and polyurethanemaking it ideal for diverse transformer coil applications. Its design allows for both standard and customized shapes, ensuring flexibility for your manufacturing needs.

Advanced Safety and Precision Controls

Safety is paramount with built-in over-temperature shutoff and leakage protection. The automatic digital temperature controller ensures precise regulation with an accuracy of 1C, supporting temperatures up to 150C. Optional features include forced air circulation for enhanced heating uniformity, tailored for the highest production standards.

FAQs of Epoxy Resin Casting Molds For Dry Type Transformer Use:

Q: How does the epoxy resin casting mold benefit transformer coil production?

A: This mold ensures precise and repeatable coil shapes through high-precision CNC machining and a polished, anti-stick surface. Its compatibility with various resins and core configurations streamlines production, while durable construction supports high-cycle use.Q: What resins are compatible with the ERCMDT-2024 casting mold?

A: The mold is engineered for use with epoxy, polyester, and polyurethane resins, providing manufacturers with flexibility to choose the optimal material for their specific transformer requirements.Q: When should routine maintenance be performed to maximize mold life?

A: Routine maintenance should be conducted after each casting cycle, focusing on cleaning, inspecting the anti-stick surface, and checking for wear. Following the manufacturers guidelines helps achieve the maximum mold lifespan of up to 1000 cycles.Q: Where can the casting mold be utilized?

A: The mold is designed for application in transformer manufacturing facilities, particularly for the production of both medium and high voltage dry type transformer coils. It is suited for both domestic and international transformer markets.Q: What is the process of demolding after casting?

A: Demolding is accomplished through either a mechanical or hydraulic system, depending on setup. These systems ensure safe, efficient removal of finished coils, minimizing product defects and mold wear.Q: How does the mold ensure operator safety during use?

A: Safety features such as over-temperature shutoff and leakage protection are integrated, and an automatic temperature controller minimizes the risk of overheating. These attributes safeguard both personnel and product integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Epoxy Resin Casting Molds For Dry Type Transformer Use

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220 V / 380 V

Type : Other Ovens, Mold for Dry Type Transformer Coil Casting

External Size : 580 x 440 x 380 mm

Temperature Range : 50C 180C

HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V, 50Hz

Type : Other Ovens, Automatic Vacuum Casting Machine

External Size : 1020 800 1800 mm

Temperature Range : Room temperature to 300C

Industrial Vacuum Drying Oven Heating By Gas Burner For Transformer Drying

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380 V / 415 V / 3 Phase

Type : Other Ovens, Vacuum Drying Oven

External Size : Customized as per requirement

Temperature Range : Ambient to 180C

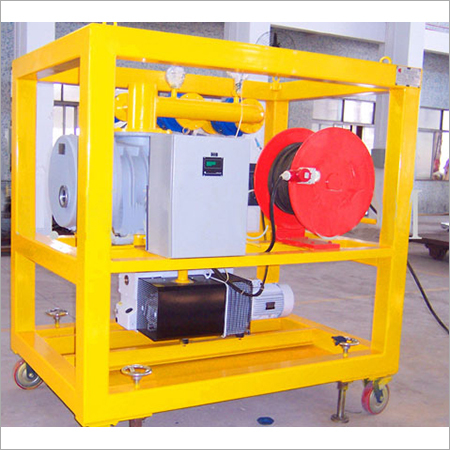

Transformer Movable vacuum pumping unit

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380V/415V, 3 Phase, 50/60 Hz

Type : Other Ovens, Transformer Movable Vacuum Pumping Unit

External Size : Customized as per requirement

Temperature Range : Ambient to 80C (heating system enabled)

Send Inquiry

Send Inquiry