Paper Taping Machine

Price 10000 USD ($)/ Set

Paper Taping Machine Specification

- Dimension (L*W*H)

- 1100 mm x 600 mm x 1200 mm

- Load Loss

- Minimal mechanical load loss

- Coil Material

- Copper/Aluminum (for winding compatibility)

- Capacity

- Ideal for coil/tape widths up to 100 mm

- Operating Temperature

- 0C to 45C

- Cooling Type

- Air cooled

- Standard

- ISO 9001:2015 Certified

- Rated Voltage

- 220V

- Product Type

- Semi-Automatic Paper Taping Machine

- Material

- Mild Steel body, precision rollers

- Output

- Consistent taping output per cycle

- Frequency (MHz)

- 50/60

- Efficiency

- High operational efficiency (approx. 94%)

- Phase

- Single Phase

- Usage

- Paper tape winding for transformer and coil assemblies

- Coil Structure

- Supports Circular/Rectangle Coils

- Coil Number

- Single or Multiple Pass (configurable)

- Power Scope

- 220V-240V AC supply

- Weight

- Approx. 150 kg

- Drive System

- Heavy duty geared motor

- Control Panel

- Digital speed and tension control

- Safety Feature

- Emergency stop switch, interlocking covers

- Roller Material

- Hardened steel for uniform tension

- Noise Level

- <70 dB

- Tape Core Size

- Standard 3 inch

- Speed Adjustment

- Variable (mechanical/electronic)

- Maintenance

- Easy access for routine service

- Max Tape Roll Diameter

- Up to 300 mm

Paper Taping Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Paper Taping Machine

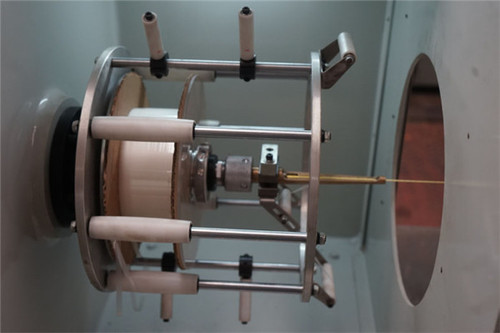

PAPER TAPING MACHINE

The machine is specially used to make round and rectangle wires, one layer or several layers of paper, fiberglass or other insulations can be wrapped on the wires continuously. It mainly consists of wire pay-off device, straighten unit, wrapping system, traction device, rewinding system, driven system and controlling system, etc.

| Production range | 5-80mm2 |

| Conductor dimension | Thickness 0.8-6mm Width 3.0-25.0mm |

| Layers of taping paper | As per need |

| Taping pitch | 6-30mm |

| Production speed | 1-15m/min |

Advanced Control and Consistency

Equipped with digital speed and tension controls, the machine offers precise adjustments for various coil sizes and tape widths. The hardened steel rollers and high-efficiency drive system guarantee stable taping performance, making it suitable for demanding industrial applications. Maintenance-friendly design and minimal mechanical load loss streamline daily operations.

Enhanced Safety and Reliability

Safety features, including an emergency stop switch and interlocking covers, provide a secure working environment. The machine is constructed with a robust mild steel body, ensuring durability and long-lasting performance even in heavy-duty usage. Its reliable output supports multiple coil winding passes, critical for transformer manufacturing.

FAQs of Paper Taping Machine:

Q: How does the Paper Taping Machine maintain uniform tape tension during operation?

A: The machine utilizes precision hardened steel rollers and a heavy-duty geared motor that work in tandem to maintain uniform tape tension, ensuring consistent winding quality for transformer and coil assemblies.Q: What is the maximum tape roll diameter and core size compatible with this machine?

A: The Paper Taping Machine supports tape rolls with a diameter up to 300 mm and uses a standard 3-inch tape core, accommodating a wide range of industrial tape products.Q: What safety features are included in the Paper Taping Machine?

A: For operator safety, the machine is equipped with an emergency stop switch and interlocking covers that prevent access during operation. These features help ensure a safe and controlled working environment.Q: When should routine maintenance be performed on the machine?

A: Routine maintenance should be carried out regularly as per the manufacturers recommendations, which typically include cleaning, lubrication, and inspection of mechanical components for optimal efficiency and longevity.Q: Where is this machine suitable for use, and who typically uses it?

A: This Paper Taping Machine is ideal for transformer and coil assembly facilities, commonly used by manufacturers, distributors, exporters, and suppliers in the electrical engineering industry.Q: What process does the machine follow for winding tape on coils?

A: The process begins with setting the coil structure (circular or rectangular), adjusting speed and tension on the digital panel, and then initiating the taping cycle. Multiple passes can be configured as needed for specific requirements.Q: What are the key benefits of using this Paper Taping Machine?

A: Key benefits include high operational efficiency, consistent taping output, reduced noise levels, robust safety and reliability, and easy maintenance, making it a preferred choice for professional coil and transformer assembly operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Insulation Material Category

Fiber Glass Taping Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 , , Unit

Weight : Approx. 350 kg

Operating Temperature : 5C to 50C

Efficiency : High operational efficiency, up to 95%

Dimension (L*W*H) : 2200 mm x 900 mm x 1300 mm

Paperboard Cutting Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Weight : Approx. 9001200 kg

Operating Temperature : 5C to 45C

Efficiency : High

Dimension (L*W*H) : 2100 x 1500 x 1400 mm

Layer Insulation Folding Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Weight : Approx. 450 kg

Operating Temperature : 5C to 45C

Efficiency : > 98%

Dimension (L*W*H) : 2100 mm x 950 mm x 1180 mm

Transformer gas drying oil

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Weight : 200 kg (standard drum)

Operating Temperature : 10C to +90C

Efficiency : High efficiency for insulation and moisture removal

Dimension (L*W*H) : Drum: approx. 580 890 mm (diameter height)

Send Inquiry

Send Inquiry