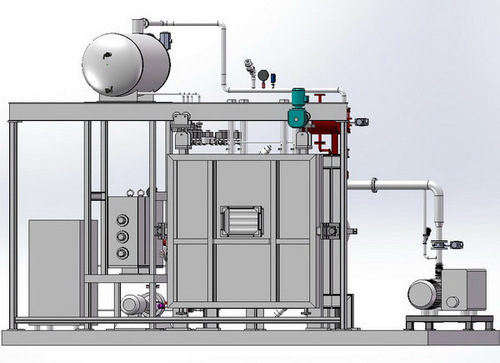

Transformer Oil Filtration Machine

Price 10000 USD ($)/ Unit

Transformer Oil Filtration Machine Specification

- Control Mode

- Automatic/Manual

- Heating Method

- Electric Heating Element

- Accuracy

- 1C

- Condition

- New

- Heating Capacity

- 50 to 500 kW (varies by model)

- Power Source

- Electric

- Type

- Vacuum Oil Filtration Machine

- Model

- TOFM-1000

- External Size

- Customizable as per requirement

- Volume

- 1000 Litres/hour (processing rate)

- Temperature Range

- Ambient to 120C

- Material

- Mild Steel with powder coating

- Dimension (L*W*H)

- 1800 x 1200 x 1600 mm (standard model)

- Power

- 10 kW 100 kW (depending on model)

- Voltage

- 380V / 415V / 440V, 3 Phase

- Surface Finish

- Powder Coated

- Protection Devices

- Overload, Overheat, Emergency Stop

- Oil Inlet/Outlet Diameter

- DN32/38 mm

- Pump Flow Rate

- 1800 3000 LPH

- Dielectric Strength Improvement

- Up to 70 kV

- Mobility

- Mounted on Skid with Heavy Duty Wheels

- Particle Removal

- 1 micron

- Working Pressure

- 0.3 MPa

- Oil Heater Material

- Stainless Steel Heater

- Filtration Stages

- 2 to 3 Stage Filtration with Pre & Fine Filters

- Vacuum Level

- -0.08 to -0.099 MPa

- Display Interface

- Digital Control & Monitoring Panel

- Application

- Transformer Oil, Insulating Oil Purification

- Water Removal

- 5 ppm Final Moisture Content

- Oil Tank Capacity

- 20-100 Liters (depending on model)

- Noise Level

- 70 dB(A) at 1 meter

Transformer Oil Filtration Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

About Transformer Oil Filtration Machine

VACUUM OIL PURIFIER

Description : The machine is mainly used for electric power department and industries to deal with various oils such as transformer oil, mutual oil, switch oil, dielectric oil and so on. The oil will be dehydrating, degassing and purifying with high performance and high speed.

Main Features

- This machine is high effective and portable, which is very suit to operate on line. Also it can be used to dry the electric equipment and input the oil into the electric equipment under the vacuum state

- High vacuum limiting vacuum less than 5pa, working vacuum less than 35pa

- High absorption speed, absorption speed power more than 333L/s

- Duplex 3D stereo-evaporation technology, eliminating the liquid water very effectively

- Automatic pressure protection, temperature control and oil level control

- Low noise, easy operation and maintenance

Reliable and Precise Oil Filtration

This advanced oil filtration machine ensures transformer oil is free from harmful moisture and particulates. It provides optimal purification via a multi-stage filtration process and a powerful vacuum system, boosting oil dielectric strength for improved transformer performance and safety. The digital control panel offers precise monitoring and automatic or manual operation modes for tailored usage.

Robust Construction and Versatile Application

Constructed from mild steel with a powder coating, this system endures demanding environments. Its stainless steel heating element and skid-mounted design enable simple relocation and reliable operation in diverse industrial settings. Compact yet powerful, it suits both onsite and workshop-based maintenance needs, maintaining transformers at peak efficiency.

User Safety and Intelligent Control

Safety is paramount with integrated protections including overload, overheat, and emergency stop features. Operators can rely on the digital interface for real-time control and monitoring. The temperature control ranges up to 120C with an excellent 1C accuracy, making the unit suitable for a variety of transformer oils and working scenarios.

FAQs of Transformer Oil Filtration Machine:

Q: How does the Transformer Oil Filtration Machine improve the quality of transformer oil?

A: The machine uses a multi-stage filtration process combining pre and fine filters along with a high-efficiency vacuum chamber. This removes particles down to 1 micron and moisture content to below 5 ppm, which enhances the oils dielectric strength up to 70 kV, contributing to better transformer safety and longevity.Q: What types of oils can be purified with this filtration machine?

A: It is primarily designed for transformer oil and insulating oil purification but can handle similar mineral-based oils used in electrical equipment, ensuring compatibility with a wide range of industrial applications.Q: When is it necessary to use this Transformer Oil Filtration Machine?

A: Use the machine whenever transformer oil shows signs of contamination, moisture ingress, or decreased dielectric strength. Routine purification is recommended during transformer installation, maintenance, or scheduled oil testing to maintain optimal equipment performance.Q: Where can the machine be installed and operated?

A: Due to its skid-mounted design with heavy-duty wheels and customizable size, the unit can be easily transported and installed at substations, workshops, transformer manufacturing sites, or repair facilities across India or export destinations.Q: What benefits does the digital control and monitoring panel provide?

A: The integrated digital interface allows for precise control of filtration parameters, real-time monitoring of system performance, and easy switching between automatic and manual modes. This enhances operational convenience, accuracy, and safety.Q: How is operator safety ensured during the filtration process?

A: Multiple safety mechanisms such as overload, overheat, emergency stop, and thermal cut-offs are incorporated. These features protect both operators and equipment from potential hazards during filtration and heating operations.Q: Can the filtration process be customized based on specific requirements?

A: Yes, the machine supports both automatic and manual operation, adjustable heating capacity, and customizable external dimensions. This flexibility allows operators to tailor the process to meet different oil purification needs and site conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Industrial Vacuum Drying Oven Heating By Gas Burner For Transformer Drying

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Type : Other Ovens, Vacuum Drying Oven

Power Source : Other, Natural Gas/LPG

Voltage : 380 V / 415 V / 3 Phase

Transformer Vacuum Oil-filling equipment

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Type : Other Ovens, Oil Filling Equipment

Power Source : Electric

Voltage : 380V / 50Hz

Vacuum Epoxy Resin Casting Machine Chamber For Dry Type Transformer Reactor Making

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Type : Other Ovens, Vacuum Epoxy Resin Casting Machine Chamber

Power Source : Electric

Voltage : 380V / 415V / 440V, 3 Phase

Epoxy Resin Casting Molds For Dry Type Transformer Use

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Type : Other Ovens, Epoxy Resin Casting Mold

Power Source : Other, Electrical

Voltage : 220V/380V, 50/60Hz

Send Inquiry

Send Inquiry