2.5*1.6*1.6m Vacuum Annealing Furnace

Price 10000 USD ($)/ Unit

2.5*1.6*1.6m Vacuum Annealing Furnace Specification

- Control Mode

- Programmable Digital Temperature Controller

- Condition

- New

- Heating Method

- Electric Resistance Heating

- Heating Capacity

- Up to 1200C (depending on model)

- Power Source

- Electric

- Accuracy

- 1C

- Type

- Vacuum Annealing Furnace

- Model

- Vacuum Annealing Furnace 2.5-1.6-1.6

- Internal Size

- Customized or as per chamber specification

- External Size

- 2.5*1.6*1.6m

- Volume

- Approx. 6.4 m

- Air Flow

- Vacuum (forced air not applicable)

- Temperature Range

- Room temperature to 1100-1200C

- Material

- High quality stainless steel chamber, mild steel exterior

- Dimension (L*W*H)

- 2.5m x 1.6m x 1.6m

- Power

- 65~90 kW (model dependent)

- Voltage

- 380V / 415V, 3 Phase

- Surface Finish

- Powder coated exterior, polished inner chamber

- Thermal Insulation

- High-density ceramic fiber insulation

- Vacuum Level

- Up to 10 Pa (high vacuum)

- Cooling Method

- Natural cooling with optional rapid cooling system

- Customization

- Available for different chamber sizes and power ratings

- Safety Features

- Over-temperature protection, automatic power-off, leakage protection

- Door Type

- Front opening, manual or hydraulic

- Application

- Suitable for annealing, degassing, tempering, heat treatment of metals/alloys

- Data Logging

- Yes, USB/RS485 interface options

- Observation Window

- Available (optional)

- Controller Type

- PID microprocessor based

2.5*1.6*1.6m Vacuum Annealing Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

About 2.5*1.6*1.6m Vacuum Annealing Furnace

Main Technical Data:

- Equipment Type: Single-chamber, horizontal

- The maximum installed furnace capacity: 5000kg

- Effective heating area: 2500 x 1600 x1600mm (L x W x H)

- Maximum working temperature: 900

- Temperature uniformity: 5

- The maximum heating rate: 160 / h (adjustable)

- Furnace surface temperature: 30

- Ultimate vacuum 30Pa (empty, cold)

- Cold leakage rate: 50Pa.L / s

- Heating power: 150KW

- Temperature control: automatic control of three-stage program

Advanced Thermal Processing

The furnace excels at high-vacuum thermal treatments including annealing, degassing, tempering, and general heat treatment for metals and alloys. Its high performance and flexibility support reliable results for industrial and research applications.

Superior Build and Safety

Engineered with a polished stainless-steel chamber and powder-coated exterior, the unit ensures durability. Comprehensive safety features include leakage protection, over-temperature safeguards, and automatic power cut-off to protect both users and equipment.

Precise Control and Data Management

Featuring a PID microprocessor-based controller, the furnace maintains temperature accuracy within 1C. Optional observation windows, rapid cooling, and USB/RS485 connectivity provide versatile operation and robust data logging.

Customizable Solutions

Manufacturers, exporters, and suppliers across India benefit from flexible options to match diverse process requirements. Chamber size and power rating customization enable tailored performance for different operational scales.

FAQs of 2.5*1.6*1.6m Vacuum Annealing Furnace:

Q: How does the vacuum annealing furnace achieve high vacuum levels for heat treatment processes?

A: The furnace uses specialized vacuum pumps and seals to attain up to 10 Pa, creating a contamination-free atmosphere essential for high-purity metal annealing and degassing.Q: What safety features are included with the Vacuum Annealing Furnace 2.5-1.6-1.6?

A: This model includes over-temperature protection, automatic power-off, and leakage protection to ensure safe and reliable operation during all heat treatment cycles.Q: When is rapid cooling recommended over natural cooling?

A: Rapid cooling is advised when fast cycle times or specific metallurgical results are required, especially for temperature-sensitive alloys, while natural cooling is suitable for standard processes.Q: Where can this vacuum furnace be installed, and what are its installation requirements?

A: The furnace is designed for industrial facilities and research labs. It requires adequate space, three-phase power (380V/415V), and proper ventilation for safe operation.Q: What processes and materials are compatible with the furnaces capabilities?

A: It supports annealing, degassing, tempering, and general heat treatments for metals and alloys, providing uniform results up to 1200C, with chamber size and power customizable to material needs.Q: How does the PID controller improve process accuracy and repeatability?

A: The PID microprocessor-based controller maintains temperature to within 1C, ensuring consistent heat profiles and reliable results across repeated operations.Q: What is the benefit of having data logging and USB/RS485 interfaces?

A: Data logging enables traceability and analysis for process optimization, while USB/RS485 interfaces allow for seamless integration with monitoring systems or data export for documentation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

HS-300A Automatic Vacuum Casting Machine(Dynamic Material Mixing)

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1200 x 800 x 1560 mm

Voltage : 220V / 380V

Type : Other Ovens, Vacuum Casting Machine

Control Mode : Automatic (PLC Control)

Vacuum Drying And Oil Filling Machine Plant For Transformer Production

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 4300 x 1950 x 2400 mm

Voltage : 380V/50Hz

Type : Other Ovens, Vacuum Drying and Oil Filling Plant

Control Mode : Automatic PLC Control

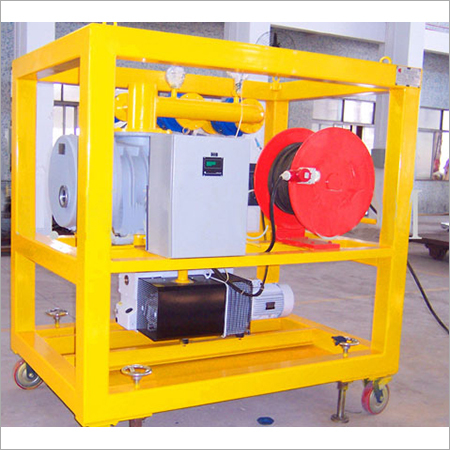

Movable Vacuum System

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1000 x 850 x 1800 mm

Voltage : 220V/50Hz

Type : Other Ovens, Movable Vacuum System

Control Mode : Digital PID Controller

Transformer Movable vacuum pumping unit

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customized or standard: approx. 1600 x 950 x 1350 mm

Voltage : 380V/415V, 3 Phase, 50/60 Hz

Type : Other Ovens, Transformer Movable Vacuum Pumping Unit

Control Mode : Automatic / Manual Switch

Send Inquiry

Send Inquiry