HS-300A Automatic Vacuum Casting Machine(Dynamic Material Mixing)

Price 10000 USD ($)/ Unit

HS-300A Automatic Vacuum Casting Machine(Dynamic Material Mixing) Specification

- Heating Method

- Electric Heating

- Accuracy

- 1C

- Control Mode

- Automatic (PLC Control)

- Heating Capacity

- 15 kW

- Condition

- New

- Power Source

- Electric / Compressed Air

- Type

- Vacuum Casting Machine

- Model

- HS-300A

- Internal Size

- 400 x 400 x 350 mm

- External Size

- 1200 x 800 x 1560 mm

- Volume

- 30 L

- Air Flow

- Dynamic Mixing System

- Temperature Range

- Room Temp - 200C

- Material

- Stainless Steel

- Dimension (L*W*H)

- 1200 x 800 x 1560 mm

- Power

- 3 Phase, 50 Hz

- Voltage

- 220V / 380V

- Surface Finish

- Polished

- Weight

- Approx. 350 kg

- Safety Features

- Overheat Protection, Door Interlocking

- Mixing Speed

- Adjustable, up to 150 rpm

- Material Mixing Method

- Dynamic automatic mixing with low-noise motor

- Timer Function

- Digital programmable timer

- Application

- Jewelry, Industrial Prototype, Dentistry

- Vacuum Degree

- -0.098 MPa

- Cooling Type

- Air Cooling

- Display

- LCD Touch Screen Control Panel

- Noise Level

- 65 dB

- Casting Chamber

- Transparent viewing window

HS-300A Automatic Vacuum Casting Machine(Dynamic Material Mixing) Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

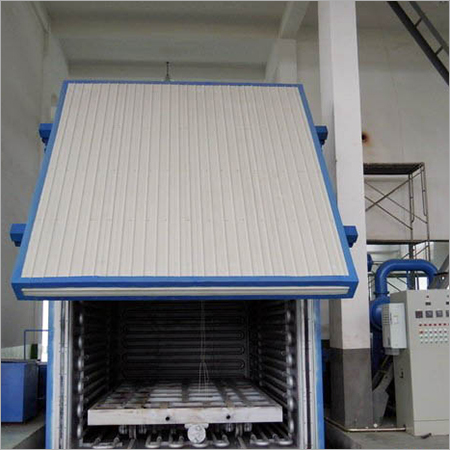

About HS-300A Automatic Vacuum Casting Machine(Dynamic Material Mixing)

Description:

Our vacuum casting machine adopt industrial computer controlling & manual controlling modes. Automatic record material tank, casting tank, mould temperature, vacuum degree. Preset material tank feeding rate.

Material mixing tanks adopt electrical heating, automatic temperature control. Casting tank adopts electrical heating plate directly heating. Each heating system has rock wool insulation. Casting tank equipped with stainless steel plate shield. Mixing tank equipped with steel plate shield. Surface temperature of the insulation is not higher than room temperature by 20.

Dynamic Material Mixing for Superior Results

Utilizing advanced dynamic automatic mixing, the HS-300A ensures thorough blending of materials with minimal noise. The adjustable mixing speed up to 150 rpm and robust low-noise motor guarantee uniform consistency, enhancing precision and quality in casting projects for jewelry, prototypes, and dental items.

Intuitive Controls & Safety Features

The machine is equipped with an LCD touch screen control panel for user-friendly operation. Its programmable digital timer allows for precise workflow management, while built-in overheat protection and door interlocking keep work environments secure and comfortable for operators.

Transparent Viewing Chamber & Efficient Cooling

A transparent casting chamber provides full visibility during processes, enabling real-time monitoring and better quality control. The air cooling system preserves the optimal temperature and extends equipment lifespan, reducing maintenance needs. This combination assures dependable casting performance every time.

FAQs of HS-300A Automatic Vacuum Casting Machine(Dynamic Material Mixing):

Q: How does the HS-300A Automatic Vacuum Casting Machine operate its dynamic material mixing system?

A: The HS-300A uses a low-noise motor to activate dynamic automatic mixing, ensuring even distribution of materials at adjustable speeds up to 150 rpm. This system provides a consistent blend, crucial for high-quality casting.Q: What types of applications is the HS-300A suitable for?

A: This machine is ideal for casting jewelry, fabricating industrial prototypes, and dental modeling. Its precision control and advanced mixing technology make it versatile for various professional settings.Q: When should I use the programmable digital timer feature?

A: The digital timer allows users to set and automate process durations, ensuring repeatable results and efficient workflow management. Its recommended for batch casting or time-sensitive production cycles.Q: Where is the HS-300A most commonly installed?

A: Common installations include jewelry workshops, dental laboratories, industrial prototype facilities, and manufacturing units dealing with precision casting in India and globally.Q: What process ensures optimal vacuum during casting operations?

A: The HS-300A achieves a vacuum degree of -0.098 MPa, vital for minimizing air entrapment and defects during casting. Its transparent chamber lets users monitor the process for consistent quality assurance.Q: How does the air cooling system benefit the casting process?

A: Air cooling efficiently maintains suitable operating temperatures, minimizing thermal stress on components, and enhancing the longer-term reliability and safety of the machine during continuous operation.Q: What are the main benefits of using the HS-300A Automatic Vacuum Casting Machine?

A: Users benefit from high-accuracy casting (1C), safe operation due to multiple protective features, reduced noise, automated control, and versatility across diverse industries, all supported by durable stainless steel construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Silicon steel Vertical-load Vacuum Annealing Furnace

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel, HighTemperature Alloy

Power : 120 kW

Control Mode : PID Automatic Control

Accuracy : 1C

Vacuum Drying Oven Or Chamber For Power Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel / Stainless Steel

Power : 1500 kW

Control Mode : PLC & Manual Control

Accuracy : 2C

Vacuum Drying And Oil Filling Machine Plant For Transformer Production

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Power : 40 kW

Control Mode : Automatic PLC Control

Accuracy : 1C

Kerosene vapor-phase drying equipment

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : HighGrade Stainless Steel (Inner Chamber), Reinforced Carbon Steel (Outer Structure)

Power : 3275 kW (depending on model)

Control Mode : PLC/Automatic Control

Accuracy : Temperature control 1C

Send Inquiry

Send Inquiry