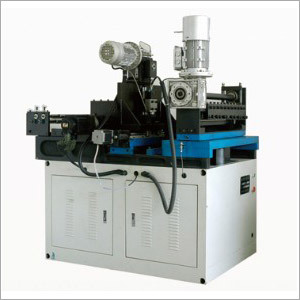

CRGO / CRNGO Silicon Steel Slitting Line

Price 10000 USD ($)/ Unit

CRGO / CRNGO Silicon Steel Slitting Line Specification

- Drive Motor

- Servo/AC Drive Motor

- Product Type

- Industrial Coil Slitting Machine

- General Use

- Slitting CRGO/CRNGO Coils for Transformer and Electrical Industry

- Material

- CRGO / CRNGO Silicon Steel

- Type

- Slitting Line

- Capacity

- Up to 10-15 Tons per coil

- Weight (kg)

- Approx 18000 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- Cutting Speed

- 60-120 m/min

- Cutting Thickness

- 0.18 mm to 0.50 mm

- Cutting Function

- Precision Slitting of CRGO/CRNGO Silicon Steel Coils

- Cooling System

- Industrial Oil Cooling

- Drive Type

- AC Motor Driven

- Voltage

- 380V / 415V / 440V, 3 Phase, 50Hz / 60Hz

- Dimension (L*W*H)

- Approx 16500 x 5000 x 1900 mm

- Feature

- High accuracy, fast operation, low burr slitting

- Color

- Customized (Standard: Blue/Gray)

- Motor

- High-efficiency AC Motor

- Mechanical Precision

- Up to 0.05 mm

- Software Detail

- PLC Controlled Automation

- Cutting Method

- Rotary/Circular Blade Slitting

- Control System

- PLC with Touch Screen HMI

- Cutting Material

- Cold Rolled Grain Oriented (CRGO) or Non Grain Oriented (CRNGO) Silicon Steel

- Cutting Area

- Up to 1600 mm width

- Edge Trimming

- Online Edge Trimming Device

- Noise Level

- 75 dB

- Recoiler Type

- Power Recoiler with Hydraulic Push-off

- Installation

- On-site Installation and Training Provided

- Strap Winder

- Included for Coil Handling

- Safety Devices

- Emergency Stop, Safety Guards, Overload Protection

- Operator Panel

- User-friendly Soft Key Operation Panel

- Decoiler Type

- Hydraulic Expandable Decoiler with Coil Car

- Min. Coil ID/OD

- ID: 508/610 mm, OD: up to 1800 mm

- Number of Slitting Blades

- Up to 20 (customizable as per requirement)

- Line Speed Control

- Inverter/Variable Frequency Drive

- Power Consumption

- Approx 35-55 kW (Line dependent)

- Operating Temperature

- 5C to 45C

- Lubrication System

- Automatic Centralized Lubrication

- Guiding System

- Automatic Edge Guiding System with Sensors

CRGO / CRNGO Silicon Steel Slitting Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About CRGO / CRNGO Silicon Steel Slitting Line

Crgo Silicon Steel Slitting Line

Description : The Silicon Steel Slitting Line Is Especially For Silicon Steel (Crgo) Coil Longitudinal Slitting. The Wide Coil (1000/1250Mm) Shall Be Opened And Cut Into Required Width Strips And Then Rewinded Into Rolled Coil. The Main Working Flow Is Coil Loading Decoiling Guiding Slitting Tensioning Recoiling Discharging.

Main Components Of Silicon Steel Slitting Line:

- Coil Car For Coil Loading

- Hydraulic Dc Powered Decoiler

- Coil Sheet Feeding System

- Slitter (Vf Speed Controlling)

- Tensioning System

- Hydraulic Dc Powered Recoiler

- Coil Car For Discharging

- Controlling Cabinet

- Dc Driving For Slitting And Recoiling

- Plc Automatic Controlling, Vf Speed Adjusting

- High Quality Alloy Blade For Precision Working

- International Famous Brand Electrical And Pneumatic Elements

Precision Slitting for Electrical Industry

Our slitting line is specifically designed for precise and efficient processing of CRGO and CRNGO silicon steel coils. The fully automatic system minimizes burr formation and ensures high-quality slit strips, enhancing productivity and material performance in transformer and electrical applications.

Automated Operation with User-Friendly Interface

Equipped with a PLC-controlled automation system and touch screen HMI, the line offers easy operation and optimal process monitoring. The user-friendly soft key panel allows operators to configure settings efficiently, while sensor-driven edge guiding guarantees accuracy throughout the slitting process.

Enhanced Safety and Reliability

Safety is prioritized with features such as emergency stop, safety guards, and overload protection. Centralized automatic lubrication and robust cooling systems reduce downtime and keep the machine performing optimally under varied operational demands. Expert installation and on-site training are included for seamless startup.

FAQs of CRGO / CRNGO Silicon Steel Slitting Line:

Q: How does the CRGO/CRNGO Silicon Steel Slitting Line achieve high precision during the slitting process?

A: This slitting line utilizes automatic edge guiding with sensors, online edge trimming devices, and rotary/circular blade cutting to maintain mechanical precision up to 0.05 mm. The PLC-controlled system ensures every slit strip meets strict accuracy requirements, ideal for transformer and electrical applications.Q: What are the main benefits of using a fully automatic slitting line for CRGO and CRNGO coils?

A: A fully automatic line improves productivity with rapid coil handling, minimizes manual intervention, and reduces operational errors. Automated lubrication, inverter-controlled speed, and safety systems further enhance consistency and reduce maintenance needs.Q: When is edge trimming performed in this slitting line, and why is it important?

A: Edge trimming is conducted simultaneously with slitting, using an integrated online device. It ensures clean, uniform strip edges, which is crucial for transformer core manufacturing and reduces wastage in subsequent processes.Q: Where is the slitting line typically installed, and is on-site support provided?

A: The equipment is primarily installed at transformer and electrical manufacturing facilities. On-site installation and comprehensive operator training are provided to facilitate smooth commissioning and optimal usage.Q: How customizable is the number of slitting blades on this machine?

A: The slitting line accommodates up to 20 blades, and the configuration can be tailored based on specific production requirements. This flexibility allows for a range of strip widths and maximizes production efficiency.Q: What types of coils can the slitting line process, and what are the supported coil dimensions?

A: It is suitable for both CRGO and CRNGO silicon steel coils, with a minimum coil ID of 508/610 mm and maximum OD up to 1800 mm. The line can handle coils up to 1015 tons in weight and widths up to 1600 mm.Q: What safety features are built into the slitting line to protect operators and equipment?

A: The slitting line includes emergency stop controls, safety guards, overload protection, and a centralized lubrication system to maintain safe operation and safeguard both operators and machinery during use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Core Cutting Machine Category

Heavy Duty Transformer Amorphous Cutting Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Automatic : Other, Fully automatic operation

Material : Other, Amorphous steel, Silicon steel

Control System : Intelligent PLC with HMI

Type : Other, Heavy Duty Amorphous Strip Cutting Machine

S11, S13 Triangular solid core power transformer core Diagonal Slitting Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Automatic : Other, Automatic operation

Material : Other, Coldrolled grainoriented silicon steel (CRGO), mild steel body

Control System : Integrated PLCbased

Type : Other, Diagonal Slitting Machine for Transformer Core

Multi-hole Horizontal cutting machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Automatic : Other, Fully Automatic

Material : Other, Mild steel, Stainless steel, Aluminum

Control System : PLC based control system

Type : Other, Horizontal Cutting Machine

Swing Shear and Punching Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Automatic : Other, No (Manual operation)

Material : Other, Mild Steel

Control System : Manual Lever Control

Type : Other, Swing Shear combined with Punching

Send Inquiry

Send Inquiry