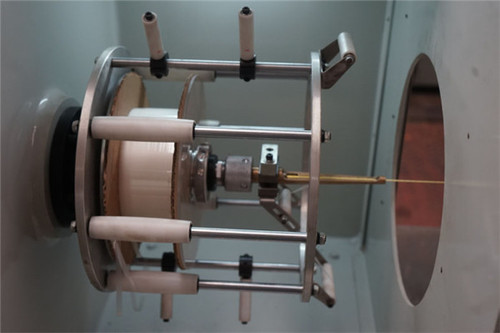

Fiber Glass Taping Machine

Price 10000 USD ($)/ Set

Fiber Glass Taping Machine Specification

- Rated Voltage

- 220V / 380V

- Capacity

- Suitable for wire diameters 1 mm to 18 mm

- Coil Material

- Compatible with copper, aluminum, iron core

- Voltage Booster Type

- Standard built-in booster

- Low Voltage

- Customizable as per client requirement

- Dimension (L*W*H)

- 2200 mm x 900 mm x 1300 mm

- Load Loss

- Minimal, depends on usage and load

- Operating Temperature

- 5C to 50C

- Standard

- Conforms to IS, CE and other relevant international standards

- High Voltage

- Customizable as per client requirement

- Cooling Type

- Air cooled

- Product Type

- Automatic Fiber Glass Taping Machine

- Material

- Sturdy metallic body with fiber glass compatibility

- Output

- 300-600 pieces per hour (varies with application)

- Frequency (MHz)

- 50 Hz

- Efficiency

- High operational efficiency, up to 95%

- Phase

- Single and Three Phase options available

- Usage

- Taping fiber glass onto wires, cables, and armature coils for insulation and binding purposes

- Coil Structure

- Parallel or cross taping structure possible

- Coil Number

- Single or multi-coil taping capability

- Power Scope

- 0.5 HP to 2 HP

- Weight

- Approx. 350 kg

- Tape Reel Diameter

- Maximum 250 mm

- Noise Level

- Below 60 dB

- Taping Speed

- 0.2 3.0 m/s (adjustable steplessly)

- Tape Width Range

- 10 mm to 50 mm

- Control Panel

- PLC based with touch screen interface

- Tape Core Size

- 76 mm

- Drive System

- Servo/AC frequency control motor

- Surface Finish

- Powder Coated

Fiber Glass Taping Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Fiber Glass Taping Machine

Fiberglass taping machine

Description

This machine is special designed for straighten and averagely taping both fiberglass or film to copper/aluminum wires, section area 5-40mm.

It is of twin-head structure, same configuration for large productivity.

By adding high frequency sintering device, this line can produce special film-taped magnet wires.

Production flow

Pay-offstraightening polishing & cleaningtaping filmvarnishingconcentric tapingvarnishingconcentric tapingvarnishingtowingbakingvarnishingbaking auxiliary towing deviceapplying self-adhering gluebakingauxiliary towinglength counting winding

Advanced Control for Versatile Taping

Equipped with a PLC-based touch screen interface, the Fiber Glass Taping Machine allows operators to tailor settings for various coil structures and wire diameters. Its servo and AC frequency motor ensure precise speed regulation between 0.2 and 3.0 m/s, enabling efficient and customizable taping processes. This flexibility supports both parallel and cross taping, maximizing adaptability in production environments.

Superior Efficiency and Quiet Operation

Designed for high output with up to 95% operational efficiency, this machine can process approximately 300 to 600 pieces per hour, depending on application. Its noise level remains below 60 dB, making it suitable for settings where minimal disruption is essential. The air-cooled system maintains optimal performance even under extended use, supporting reliable insulation and binding tasks.

Durably Built and Standards Compliant

Constructed with a powder-coated, sturdy metallic body, the Fiber Glass Taping Machine is engineered for durability and longevity. Its compatibility with various core materialscopper, aluminum, and ironexpands its applicability. Conformance to IS, CE, and international standards assures users of quality and safety in industrial operations across manufacturing, export, and supply sectors.

FAQs of Fiber Glass Taping Machine:

Q: How does the Fiber Glass Taping Machine operate for different coil structures?

A: The machine supports both parallel and cross taping structures, which can be selected through the PLC-based touch screen control. This allows operators to adapt the taping process according to specific insulation or binding requirements for various wire or coil configurations.Q: What type of materials can be processed using this taping machine?

A: It is compatible with wires and coils made of copper, aluminum, and iron cores, and designed specifically to apply fiber glass tape for effective insulating and binding purposes. The machine can handle wire diameters ranging from 1 mm to 18 mm.Q: When is it beneficial to use adjustable taping speed in production?

A: Adjustable taping speed, ranging from 0.2 to 3.0 meters per second, allows users to optimize productivity for differing wire thicknesses and application requirements, making it ideal for both high-speed and precision insulation jobs.Q: Where is the Fiber Glass Taping Machine typically installed and used?

A: It is commonly installed in wire and cable manufacturing plants, armature coil production facilities, and electrical workshops across distributor, exporter, and supplier operations in India and internationally.Q: What is the process for setting up the taping parameters on this machine?

A: Setup is straightforward using the PLC touch screen control panel. Operators select tape width, core size, taping speed, coil structure, and voltage parameters to match their specific application needs, ensuring accurate and repeatable results.Q: What are the main usage and benefits of this taping machine?

A: The machine automates the taping of fiber glass onto wires and coils, providing superior insulation and robust binding. Benefits include high efficiency, minimal load loss, low noise operation, and versatility for single or multi-coil taping, boosting both productivity and product quality compared to manual methods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Insulation Material Category

3520 phenolic paper tube - transformer insulation tube

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Cooling Type : Compatible with oilimmersed and drytype transformers

Operating Temperature : 40C to +120C (continuous duty)

Usage : Transformer insulation, electrical equipment, highvoltage coil winding support

Dimension (L*W*H) : Customizable: Common sizes OD 15300 mm, length up to 1200 mm

Paper Taping Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 , , Unit

Cooling Type : Air cooled

Operating Temperature : 0C to 45C

Usage : Paper tape winding for transformer and coil assemblies

Dimension (L*W*H) : 1100 mm x 600 mm x 1200 mm

Layer Insulation Folding Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Cooling Type : Aircooled

Operating Temperature : 5C to 45C

Usage : Layer insulation folding in transformer coil manufacturing

Dimension (L*W*H) : 2100 mm x 950 mm x 1180 mm

Paperboard Corrugating Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Cooling Type : Water cooled rollers

Operating Temperature : Up to 180C (roller surface)

Usage : Corrugating paperboard for packaging industry

Dimension (L*W*H) : 3200mm x 1300mm x 1500mm

Send Inquiry

Send Inquiry