full automatic vacuum casting machine for epoxry resin dry-type transformers

Price 10000 USD ($)/ Unit

full automatic vacuum casting machine for epoxry resin dry-type transformers Specification

- Heating Capacity

- 80 kW (standard); manufacturer customizable

- Accuracy

- 1C (temperature), Vacuum Degree 0.001 MPa

- Power Source

- Electric

- Condition

- New

- Control Mode

- PLC Full-Automatic Control, HMI Touch Screen Interface

- Heating Method

- Hot air circulation/infrared (customizable)

- Type

- Epoxy Resin Vacuum Casting Machine

- Model

- VCM-E8000A

- Internal Size

- 3500 2500 2300 mm (customizable)

- External Size

- 6000 4000 3500 mm (customizable)

- Volume

- 8000 Liters (customizable)

- Air Flow

- Variable, forced circulation system 1500 m/h

- Temperature Range

- Room temperature to 120C (programmable)

- Material

- Stainless steel (SS304) and structural steel

- Dimension (L*W*H)

- Customized; standard: 6000 4000 3500 mm

- Power

- Total installed: 100 kW

- Voltage

- 380V/415V; 3 Phase 50/60Hz

- Surface Finish

- Powder coated / sandblasted, corrosion-resistant

- Data Logging

- Full process data recording and exportable batch reports

- Vacuum Degree

- Up to -0.098 MPa

- Working Chamber

- One/two chambers with large viewing window

- Ambient Conditions

- 5C40C; up to 90% RH non-condensing

- Applicable Transformer Capacity

- 1603150 kVA (or per customer specification)

- Mixing System

- High precision static/dynamic mixing with servo agitation

- Resin Supply

- Automatic heated resin supply system with temperature and flow monitoring

- Safety Features

- Over-temperature, over-pressure, and power failure protection; automatic alarms

- Casting Method

- Vacuum pressure impregnation & casting; programmable process

- Installation & Commissioning

- On-site installation & operator training included

- Resin Tank Capacity

- 1000 L 2 (Main + Hardener tanks)

- Degassing Function

- Automatic double-stage vacuum degassing

- Pouring Speed

- Adjustable 30120 kg/min

full automatic vacuum casting machine for epoxry resin dry-type transformers Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

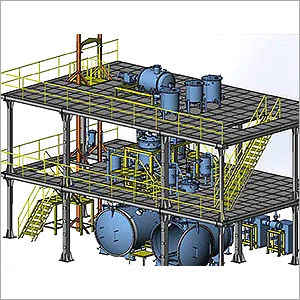

About full automatic vacuum casting machine for epoxry resin dry-type transformers

Full automatic VRC-10E vacuum casting machine for transformers is applicable for processing both mixed material with stuffing added by user and double-component pre-mixed stuffing, very flexible.

Full automatic VRC-10E vacuum casting machine configuration can be added or reduced according to users requirements. It can be modularly rigged. It is characterized by convenient installation, easy operation, and high automation.

Main features of full automatic VRC-10E vacuum casting machine:

- Perfect vacuum system: the whole process is carried out under vacuum condition.

Reliable metering system: there are two kind of metering methods based on different process requirement:

- Feeding pump + electronic scale (for casting with stuffing)

- Metering pump + static mixer (for casting various kind products)

Advanced and safe heating technology:

- Mixing tank is heated by electric heating tubes, good temperature uniformity, high precision temperature control

- Casting tank is heated directly by electric heating plate

Advanced & reliable metering and control system: controlled by computer, key process and those easy to be mis-operated are controlled interlocked; Process revising, process curve recording, process parameter adjusting, can be achieved by computer very conveniently. The whole metering control and vacuum control are all full pre-set automatic.

Precision Engineering for Optimal Transformer Casting

Designed for the rigorous demands of epoxy resin dry-type transformer production, the VCM-E8000A offers advanced vacuum casting with adjustable parameters, ensuring repeatable and high-quality results. With features such as servo-controlled high-precision mixing, programmable process control, and real-time data logging, this machine delivers consistent resin distribution and impregnation, minimizing manual oversight and production errors.

Superior Safety and User Experience

Operator safety and product integrity are paramount in the VCM-E8000A, featuring over-temperature, over-pressure, and power failure protections alongside automated alarms. The intuitive HMI touch screen and PLC full-automatic control system simplify the casting process, while comprehensive on-site installation and training ensure smooth operation and easy adaptation for staff.

FAQs of full automatic vacuum casting machine for epoxry resin dry-type transformers:

Q: How does the VCM-E8000A ensure effective degassing of epoxy resin?

A: The VCM-E8000A features an automatic double-stage vacuum degassing system, capable of achieving up to -0.098 MPa vacuum degree. This removes entrapped air and moisture from the resin, guaranteeing fewer bubbles, improved resin penetration, and superior transformer insulation properties.Q: What casting process does this machine use for transformer production?

A: The machine employs a programmable vacuum pressure impregnation and casting process. This method enables deep resin infiltration into transformer windings, optimizes curing, and allows for repeatable and efficient transformer batch production with minimal manual intervention.Q: When is the operator training provided for new installations?

A: On-site installation and operator training are included with each purchase. Training is typically scheduled immediately following installation, ensuring staff are confident in machine operation, safety protocols, and process optimization from day one.Q: Where can customized sizes and configurations be requested?

A: The manufacturer offers customization for external and internal chamber dimensions, heating systems, and control features. Customers can specify requirements during initial order discussions to tailor the machine for unique production environments or transformer sizes.Q: How is resin supply monitored and controlled during casting?

A: The VCM-E8000A is equipped with an automatic heated resin supply system that constantly monitors resin temperature and flow. This ensures consistent supply quality and optimal process control throughout the casting cycle.Q: What are the primary benefits of using this automatic vacuum casting machine for epoxy resin transformers?

A: Key benefits include precise temperature and vacuum control, high production rates (pouring speed up to 120 kg/min), minimized defects through advanced degassing, extensive data logging for traceability, and enhanced operator safety through comprehensive protection mechanisms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Epoxy Resin Casting Molds For Dry Type Transformer Use

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Type : Other Ovens, Epoxy Resin Casting Mold

Condition : New

Power Source : Other, Electrical

Air Flow : Optional forced air circulation

Kerosene Vapor Phase Drying Equipment (VPD) For Big Power Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Type : Other Ovens, Kerosene Vapor Phase Drying Equipment (VPD)

Condition : New

Power Source : Other, Electric / Diesel

Air Flow : Adjustable, up to 15000 m/h

Power Transformer Vacuum Drying Furance Manufacturing

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Type : Other Ovens, Vacuum Drying Furnace

Condition : New

Power Source : Electric

Air Flow : Forced Air Circulation

Vacuum Annealing Furnace

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Type : Other Ovens, Vacuum Furnace

Condition : New

Power Source : Electric

Air Flow : Vacuum Environment (No Air Flow)

Send Inquiry

Send Inquiry