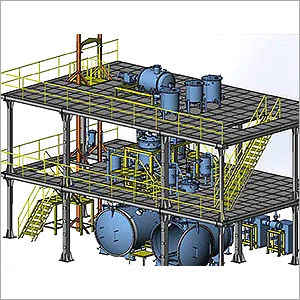

Transformer Vacuum Annealing Furnace

Price 10000 USD ($)/ Unit

Transformer Vacuum Annealing Furnace Specification

- Accuracy

- 2C

- Heating Capacity

- 3000 kg per batch

- Heating Method

- Electric Resistance Heating

- Control Mode

- Automatic PLC Control

- Power Source

- Electric

- Condition

- New

- Type

- Vacuum Annealing Furnace

- Model

- TR-ANF-1600

- Internal Size

- 1800 mm x 1500 mm x 1600 mm

- External Size

- 2800 mm x 2300 mm x 2500 mm

- Volume

- 4.3 m

- Air Flow

- Vacuum or inert gas environment

- Temperature Range

- Up to 900C

- Material

- Stainless steel chamber with high temperature insulation

- Dimension (L*W*H)

- 2800 mm x 2300 mm x 2500 mm

- Power

- 120 kW

- Voltage

- 380 V / 415 V

- Surface Finish

- Polished

- Cooling Method

- Forced air or water cooling

- Cycle Time

- 8-12 hours per batch

- Control Panel

- Touchscreen HMI interface

- Insulation Type

- High-density ceramic fiber insulation

- Door Type

- Hydraulic lifting door

- Installation

- On-site installation and commissioning support available

- Safety Features

- Over-temperature protection, Emergency shutoff

- Heat Distribution

- Uniform, multi-zone heating

- Max Vacuum Level

- 10 mbar

- Service Life

- Designed for heavy-duty, continuous operation

- Compliance

- CE and ISO certified

- Application

- Annealing silicon steel for transformer cores

Transformer Vacuum Annealing Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

About Transformer Vacuum Annealing Furnace

Commercial Value and Key Features of the Transformer Vacuum Annealing Furnace

Engineered for industrial excellence, the TR-ANF-1600 furnace is ideal for annealing silicon steel in transformer core production. Its supreme uniform heating and high-density insulation ensure energy-efficient operation. The hydraulic lifting door and touchscreen HMI provide effortless, masterful control, while multi-zone heating and forced cooling maximize batch quality. Key safety features and CE/ISO compliance set it apart. Staying ahead, it promises continuous, heavy-duty commercial use with minimal downtime and superior temperature accuracy.

Packaging, Sample Availability, and Global Supply Capacity

Samples of the Transformer Vacuum Annealing Furnace are available for quality assessment prior to final charge and order processing. Our supply ability caters to global marketsmain exports reach Europe, Asia, Africa, and America. Each unit is professionally packaged in reinforced crates for secure shipping. Orders are handled with precision and care, supporting distributor, exporter, manufacturer, supplier, and trader partnerships. Fast installation and commissioning support ensures seamless deployment at your site.

FAQs of Transformer Vacuum Annealing Furnace:

Q: How does the hydraulic lifting door enhance operation and safety of the furnace?

A: The hydraulic lifting door allows effortless, secure access to the furnace, reducing manual handling risks and improving workflow efficiency. Its design supports safe sealing and rapid batch loading in heavy-duty operations, adding an extra layer of operator protection.Q: What is the primary commercial use of the TR-ANF-1600 Transformer Vacuum Annealing Furnace?

A: This furnace is primarily used for vacuum annealing of silicon steel, which is essential in manufacturing transformer corescritical components in electrical power distribution and industrial applications.Q: When should annealing cycles be scheduled to maximize production efficiency?

A: Annealing cycles, which run for 812 hours per batch, should be coordinated with production planning. Consistent scheduling optimizes throughput and ensures continuous operation for commercial transformer core manufacturing.Q: Where is the Transformer Vacuum Annealing Furnace manufactured and distributed from?

A: The TR-ANF-1600 Furnace is manufactured in China and can be distributed or exported globally, with authorized suppliers, traders, and distributors facilitating international shipping and installation.Q: What process controls ensure precise heat treatment in this vacuum annealing furnace?

A: Automated PLC control, touchscreen HMI interface, and multi-zone, uniform heating with 2C accuracy ensure consistently masterful and precise annealing, matching strict industrial specifications.Q: How does the forced air or water cooling method benefit batch quality?

A: The forced air or water cooling system rapidly brings annealed material to the desired temperature, minimizing oxidation and distortion, which improves the mechanical and magnetic properties of silicon steel used in transformer cores.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Kerosene Vapor Phase Drying Equipment (VPD) For Big Power Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Other, Electric / Diesel

Condition : New

Type : Other Ovens, Kerosene Vapor Phase Drying Equipment

Volume : 30000 L to 70000 L

full automatic vacuum casting machine for epoxry resin dry-type transformers

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Power Source : Electric

Condition : New

Type : Other Ovens, Epoxy Resin Vacuum Casting Machine

Volume : 8000 Liters (customizable)

HS-35A Vacuum Drying Oven Euipment With Vacuum Variable Pressure Changing Procedure

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Condition : New

Type : Other Ovens, Vacuum Drying Oven

Volume : 64 L

Power Transformer Vacuum Drying Furance Manufacturing

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Condition : New

Type : Other Ovens, Horizontal/Vertical type Vacuum Drying Furnace

Volume : 10,000 to 50,000 L (customized sizes available)

Send Inquiry

Send Inquiry