Paper Roll Slitting Machine For Insulation Paper Slitting

Price 10000 USD ($)/ Set

Paper Roll Slitting Machine For Insulation Paper Slitting Specification

- Cooling Type

- Air cooled

- Dimension (L*W*H)

- 2600 1400 1300 mm

- Standard

- CE/ISO 9001 certified

- Capacity

- Up to 150 m/min (speed)

- Rated Voltage

- 220V/380V

- Operating Temperature

- 5C to 40C

- Product Type

- Paper Roll Slitting Machine

- Material

- Insulation Kraft Paper, Pressboard

- Output

- Multiple slit rolls

- Efficiency

- Up to 98%

- Phase

- Single / Three Phase (customizable)

- Usage

- Slitting insulation paper for transformer and electrical applications

- Coil Structure

- Horizontal with reel stands

- Power Scope

- 2.25 kW (depends on model)

- Weight

- 1200 kg (approx.)

- Feeding Type

- Automatic feeding

- Max Unwinding Diameter

- 1000 mm

- Noise Level

- 75 dB(A)

- Safety Features

- Emergency stop, safety cover, sensors

- Max Rewinding Diameter

- 500 mm

- Slitting Width Range

- 301300 mm (custom cuts available)

- Control System

- PLC Automatic Control

- Drive Type

- AC Motor + Inverter Speed Regulation

- Tension Control

- Automatic magnetic powder brake

- Core Size

- 3 or customized

- Blade Material

- High-speed steel or tungsten carbide

- Slitting Precision

- 0.2 mm

Paper Roll Slitting Machine For Insulation Paper Slitting Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Paper Roll Slitting Machine For Insulation Paper Slitting

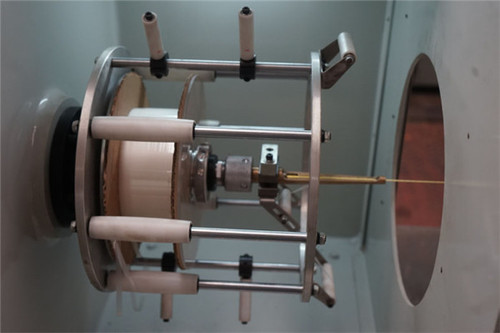

PAPER ROLL SLITTING MACHINE

The machine is used to longitudinal cutting wide paper roll into different width of paper strips and then rewind into roll. It is high precision and high speed slitting machine, also can be used to cut PP, PE, PVC, copper and aluminum foil, etc. The decoiling and recoiling have pneumatic tensioning, and decoiling has automatic calibrating for center adjusting.

| Model | HX-1300FQ | HX-1600FQ |

| Max feeding Width | 1300mm | 1600mm |

| Main Engineer Power | 6kw | 6kw |

| Speed | 80m/min | 80m/min |

| Size | 2400*2000*1300mm | 2400*2300*1600mm |

| Weight | 1200kg | 1500kg |

| Unwinding Diameter | 600mm | 800mm |

| Winding Diameter | 450mm | 450mm |

| Precision | 0.1mm | 0.1mm |

| Power | 380v 50hz | 380v 50hz |

Optimized Slitting Performance

Engineered with advanced PLC automation and AC motor speed regulation, the Paper Roll Slitting Machine ensures consistent precision up to 0.2 mm. Its automatic tension control system and robust blade material guarantee smooth, reliable cuts for insulation paper processing. Operators can achieve multiple slit rolls in a single cycle, maximizing productivity while maintaining safety and minimal noise output below 75 dB(A).

Flexible Customization and Operation

Supporting various core sizes and offering custom slitting widths, this machine adapts seamlessly to different production requirements. Its automatic feeding mechanism and horizontal coil structure with reel stands make it suitable for continuous operation. With single or three-phase power options and an air-cooled system, it is designed to function optimally within temperatures from 5C to 40C.

FAQs of Paper Roll Slitting Machine For Insulation Paper Slitting:

Q: How does this slitting machine enhance the process of insulation paper slitting?

A: The machine utilizes automatic feeding, precise PLC control, and durable blade materials to deliver accurate cuts and high throughput, streamlining operations and improving product consistency for insulation paper slitting in electrical and transformer applications.Q: What safety features are incorporated into the machines design?

A: Essential safety measures include an emergency stop function, protective safety covers, and integrated sensors, which collectively reduce operational risks and help maintain a secure working environment during usage.Q: When is it advisable to use this machine in production environments?

A: Its recommended for use when precise, high-speed slitting of insulation kraft paper or pressboard is requiredparticularly in transformer manufacturing, electrical insulation processes, and related industrial settings.Q: Where can this slitting machine be installed and operated safely?

A: Suitable for factory floors, manufacturing facilities, or workshops, installations must comply with the machines recommended operating temperature range (5C40C) and provide compatible power supply options, whether single or three-phase.Q: What is the standard process for operating the slitter machine?

A: Operators load paper rolls onto the horizontal reel stands, set desired slitting width on the PLC interface, and initiate automatic feeding. The AC motor and inverter manage speed, while tension is controlled automatically, resulting in multiple precise slit rolls per cycle.Q: How can users benefit from the automatic tension control and adjustable core sizes?

A: Automatic tension control ensures that slit materials are even and undamaged, while customization of core sizes allows users to adapt the machine for different roll formats, catering to variable production requirements with ease.Q: What materials and applications are compatible with the Paper Roll Slitting Machine?

A: It is specifically designed to slit insulation kraft paper and pressboard, supporting transformer production, electrical insulation manufacturing, and other specialized industrial uses. Custom cuts and multiple output rolls allow versatility for numerous insulation applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Insulation Material Category

3520 phenolic paper tube - transformer insulation tube

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Cooling Type : Compatible with oilimmersed and drytype transformers

Material : 3520 Phenolic Paper (Phenolic resin impregnated paper)

Efficiency : High dielectric strength, maintains insulation performance

Phase : Other, Suitable for single and threephase transformer applications

Flat Copper Wire Extrusion Line

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 , , Unit

Cooling Type : Water/forced air cooling

Material : Copper

Efficiency : Up to 98%

Phase : Three Phase

Paper Taping Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 , , Unit

Cooling Type : Air cooled

Material : Mild Steel body, precision rollers

Efficiency : High operational efficiency (approx. 94%)

Phase : Single Phase

Paperboard Corrugating Machine

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Unit

Cooling Type : Water cooled rollers

Material : Cast Iron Frame, Hardened Steel Rollers

Efficiency : High output efficiency, approx. 8590%

Phase : Three Phase

Send Inquiry

Send Inquiry