Foil Winding Machine Professional In Reactor

Price 10000 USD ($)/ Unit

Foil Winding Machine Professional In Reactor Specification

- Product Type

- Foil Winding Machine

- General Use

- Reactor Coil and Transformer Winding

- Material

- Mild Steel Frame, Aluminum and Stainless Steel Parts

- Type

- Automatic Foil Winder

- Weight (kg)

- Approx. 2600 kg

- Computerized

- Yes

- Automatic

- Fully Automatic Operation

- Control System

- PLC Controlled Panel

- Power Source

- Electric

- Power Consumption

- Approx. 12 kW

- Coil Diameter

- Min: 200 mm, Max: 1200 mm

- Winding Head

- Dual-Head System

- Winding Speed

- 2-15 m/min Adjustable

- Winding Spindle

- High Precision Steel

- Air Pressure

- 6-8 Bar

- Drive Type

- Servo Motor Driven

- Voltage

- 415V, 3 Phase, 50 Hz

- Dimension (L*W*H)

- 4500 x 1400 x 2000 mm

- Feature

- Touchscreen Interface, Digital Counter, Pneumatic Pressure Control

- Color

- Industrial Grey with Blue Accents

- Suitable For

- Copper & Aluminium Foils

- Foil Width Range

- 100-800 mm

- Operator Interface

- Touch Screen HMI

- Interlayer Insulation Placement

- Automatic

- Maximum Foil Weight

- 2000 kg

- Safety Features

- Emergency Stop, Overload Protection

- Production Capacity

- Customizable as per requirement

- Decoiler Type

- Hydraulic

- Cooling System

- Air Cooled

- Edge Alignment System

- Automatic with Sensors

- Foil Thickness

- 0.2 - 3 mm

Foil Winding Machine Professional In Reactor Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Foil Winding Machine Professional In Reactor

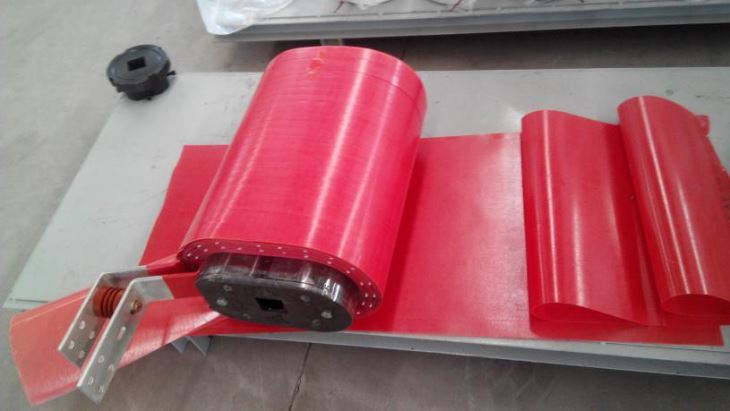

Foil Winding Machine Professional In Reactor

Foil winding machine is suitable for foil winding of all types of small and medium sized distribution transformer, instrument transformer, reactor coils and similar process foil winding. Especially suitable for the amorphous alloy transformer and wound core transformer rectangular foil winding.

Main Features:

- The tension of the decoiler is stable and it's controlled by pneumatic element. Foil and layer insulation tape whether in the winding or back are applied to a constant tension to avoid loss caused by the coil tightness. Stepless adjustment of the pressure size ensure that the whole winding process constant tension.

- Adopts our researched and developed source program and operation program, all production factors of winding, error correct, circle control, etc. Different instructions are supported by PLC control system after calculation. It is carried out and achieved by each system.

- Operating person only touch the screen of computer-human interface and input related working parameter, the same specification workpiece can be finished processing in large quantity.

- It is also operated by manual through control button, including inching, continuous moving.

- The system can store up to 30 sets of coil data for easy operation. The counter can count the winding process manually, when only wind the insulating layer, you can stop counting conveniently.

- The equipment has network communication function, easy to upgrade the system and follow-up automation program update maintenance.

- With automatic adjustment of the servo function.

High-Precision Winding for Reactor and Transformer Coils

This fully automatic foil winding machine delivers exceptional precision for reactor and transformer coil production. With a dual-head winding system and high-precision steel spindles, it guarantees accurate layering and uniform coil quality, whether processing copper or aluminium foils within its wide dimensional range.

Advanced Automation and Safety Controls

Outfitted with a PLC-controlled panel, touch screen HMI, and integrated digital counters, the machine enables user-friendly operation and precise adjustments. Safety is enhanced through emergency stops, overload protection, and a pneumatic pressure control system, providing operators with peace of mind during continuous industrial use.

Robust Construction and Efficient Performance

Engineered with a mild steel frame and premium aluminium and stainless steel components, the machine assures durability even in demanding production environments. Its air-cooled servo-driven operation supports adjustable winding speeds (2-15 m/min) and heavy foil loads up to 2000 kg, maximizing throughput and uptime.

FAQs of Foil Winding Machine Professional In Reactor:

Q: How does the automatic edge alignment system work on this foil winding machine?

A: The machine employs advanced sensors to continuously monitor the foils position during winding. This ensures precise edge alignment automatically, reducing human error and maintaining high-quality, uniform coils without manual intervention.Q: What types and sizes of foils can be processed with this machine?

A: This model supports both copper and aluminium foils with widths ranging from 100 mm to 800 mm and thicknesses from 0.2 mm up to 3 mm. It can handle coil diameters from 200 mm to 1200 mm, meeting various reactor and transformer winding requirements.Q: When should I use the automatic foil winding machine for production?

A: The machine is ideal for use in high-efficiency production environments, particularly when manufacturing reactor coils or transformer windings that require high precision, repeatability, and customizable output capacities.Q: Where is the Foil Winding Machine commonly used?

A: It is widely utilized in industrial facilities specializing in electrical coil manufacturing, including transformer plants and reactor production units, particularly by manufacturers, exporters, and suppliers across India.Q: What is the process flow for operating the foil winding machine?

A: Operation begins with setting foil parameters via the touchscreen HMI. The hydraulic decoiler feeds the foil, while automatic systems control edge alignment and interlayer insulation placement. The dual-head winding and servo motors manage the winding speed and tension, with real-time digital counters ensuring accuracy throughout the process.Q: What benefits does the PLC-controlled panel offer to operators?

A: The PLC control panel, combined with a touchscreen HMI, simplifies machine operation, allows for quick recipe changes, real-time monitoring, and immediate troubleshooting, minimizing downtime and enhancing productivity.Q: How can users ensure safety during machine operation?

A: Safety is prioritized through emergency stop functionality, overload protection systems, and pneumatic pressure control. These features, along with robust frame construction, protect both the operator and the machine during all production stages.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

LV Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Air Pressure : 68 Bar

Material : Other, Mild Steel

Winding Head : Other, Single Head

Type : Other, Automatic Coil Winder

Foil Winding Machine Professional In Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Air Pressure : 0.50.7 MPa

Material : Other, Stainless Steel, Aluminum, Copper Compatible

Winding Head : Other, Single/Double Head

Type : Other, Automatic Foil Winding

Transformer Horizontal Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Air Pressure : 68 bar

Material : Other, Mild Steel

Winding Head : Other, Single/Double Head

Type : Other, Horizontal

Foil Winding Machine Professional In Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Air Pressure : 0.5 0.7 MPa

Material : Other, Stainless Steel & Mild Steel

Winding Head : Other, Single/Double (optional)

Type : Other, Automatic Foil Winder

Send Inquiry

Send Inquiry