HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing

Price 10000 USD ($)/ Unit

HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing Specification

- Power Source

- Electric

- Control Mode

- PLC Automatic Control

- Heating Capacity

- 300C max

- Accuracy

- 1C

- Heating Method

- Electric Heating

- Condition

- New

- Type

- Automatic Vacuum Casting Machine

- Model

- HS-300A

- Internal Size

- 500 500 400 mm

- External Size

- 1020 800 1800 mm

- Volume

- 100 L

- Air Flow

- Dynamic Material Mixing with Vacuum

- Temperature Range

- Room temperature to 300C

- Material

- Stainless Steel

- Dimension (L*W*H)

- 1020 800 1800 mm

- Power

- 5 kW

- Voltage

- 220V/380V, 50Hz

- Surface Finish

- Polished

- Safety Systems

- Overload and Overheat Protection

- Max Casting Weight

- Up to 50 kg per cycle

- Vacuum Degree

- -0.098 MPa

- Mixing Method

- Dynamic Mixing Under Vacuum

- Display

- Touch Screen Interface

- Applicable Materials

- Casting Resin, Polyurethane, Silicone, and other Thermosetting Materials

- Noise Level

- 65 dB

HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

About HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing

Description:

Our vacuum casting machine adopt industrial computer controlling & manual controlling modes. Automatic record material tank, casting tank, mould temperature, vacuum degree. Preset material tank feeding rate.

Material mixing tanks adopt electrical heating, automatic temperature control. Casting tank adopts electrical heating plate directly heating. Each heating system has rock wool insulation. Casting tank equipped with stainless steel plate shield. Mixing tank equipped with steel plate shield. Surface temperature of the insulation is not higher than room temperature by 20.

Main Technical Data:

- Effective size of the casting tank: 2400x3000mm(horizontal type)

- Final material mixing tank: 300L

- Max. effective mould size: 1400x1800mm

- Magnitude of partial discharge of the casting: 10PC

- Annual production capacity:1M KVA

- Casting tank size : 2400x3000

- Main pump speed : 300L

- Casting tank working temperature : 70-85

- Casting tank limiting vacuum : 30Pa

- Casting tank leakage rate : 100Pa.L

- Casting tank working vacuum : 100-300Pa

- Casting tank working pressure : ordinary pressure

Adopt electronic scale & high viscosity pump for material feeding / Adopt dynamic material mixing

Adopt vacuum casting technology

Adopt industrial computer controlling & manual controlling modes. Automatic record material tank, casting tank, mould temperature, vacuum degree. Preset material tank feeding rate.

Material mixing tanks adopt electrical heating, automatic temperature control. Casting tank adopts electrical heating plate directly heating. Each heating system has rock wool insulation. Casting tank equipped with stainless steel plate shield. Mixing tank equipped with steel plate shield. Surface temperature of the insulation is not higher than room temperature by 20.

Efficient Dynamic Vacuum Mixing

Thanks to its dynamic material mixing under vacuum, the HS-300A ensures thorough suspension and dispersion of materials, which improves casting accuracy and reduces defects. The process eliminates trapped air, resulting in casts with excellent surface finish and material properties. The machines operational parameters can be tailored for different material types, supporting production versatility.

Advanced Touch Screen & PLC Control

The intuitive touch screen and PLC automatic control simplify machine operation, offering operators real-time monitoring and easy adjustments of temperature and mixing settings. Users can program machine cycles according to material specifications and desired casting outcomes, enhancing both safety and productivity in the manufacturing process.

Robust Safety and Low-Noise Operation

Safety features include overload and overheat protection, ensuring the HS-300A runs reliably during high-intensity usage. With a noise level of 65 dB, the machine is suitable for environments where maintaining a low acoustic footprint is important. Its stainless steel construction supports lasting durability, with polished surfaces for easy cleaning and hygienic operation.

FAQs of HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing:

Q: How does the HS-300A Automatic Vacuum Casting Machine improve casting quality?

A: The machine uses dynamic mixing under vacuum, which effectively removes air bubbles and evenly mixes materials, resulting in superior surface finishes and consistent structural integrity in cast products.Q: What materials can be processed with the HS-300A?

A: This model is suitable for casting resin, polyurethane, silicone, and other thermosetting materials, allowing manufacturers flexibility in their production lines.Q: When is dynamic vacuum mixing beneficial in casting production?

A: Dynamic vacuum mixing is particularly advantageous when high material homogeneity and defect-free casting are required. It is ideal for applications where precision and reliable results are essential.Q: Where can the HS-300A be installed and operated?

A: Designed with a compact footprint (1020 800 1800 mm) and electrical compatibility (220V/380V, 50Hz), the HS-300A can be installed in industrial settings such as manufacturing facilities, supplier workshops, or export-oriented factories in India and abroad.Q: What is the process of using the HS-300A for vacuum casting?

A: Operators load materials into the 100 L chamber, set desired temperature (up to 300C), and control parameters on the touch screen. The machine mixes the materials dynamically under vacuum, then casts the blend while maintaining consistent quality throughout the cycle.Q: How does the machine ensure user safety during operation?

A: It is equipped with overload and overheat protection systems, ensuring safe operation even during demanding production runs. The PLC control monitors all parameters for proactive management of risks.Q: What benefits do manufacturers gain by using the HS-300A?

A: Manufacturers benefit from higher quality, reduced material waste, precise thermal control, and automated operation, which collectively improve process efficiency and product consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Dry-Type Transformer Vacuum Epoxy Resin Casting Plant

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Type : Other Ovens, Vacuum Chamber with Heating System

Condition : New

Accuracy : 2C

Epoxy Resin Vacuum Casting Forming Equipment For Dry Type Transformer And CT PT Production

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Type : Other Ovens, Vacuum Casting Forming Equipment

Condition : New

Accuracy : 1C

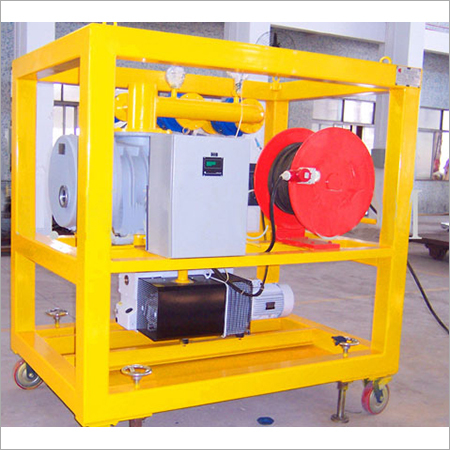

Movable Vacuum System

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Type : Other Ovens, Movable Vacuum System

Condition : New

Accuracy : 1C

Transformer Movable vacuum pumping unit

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Type : Other Ovens, Transformer Movable Vacuum Pumping Unit

Condition : New

Accuracy : High vacuum accuracy, up to 0.05 Pa

Send Inquiry

Send Inquiry