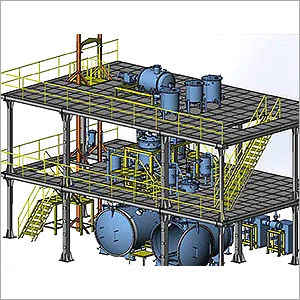

Static Mixer Vacuum Resin Casting Machine

About Static Mixer Vacuum Resin Casting Machine

VI Technical data and illustration

5.1 Stuffing bag (1000kg) opening system

- For opening stuffing bags in max. 1000kg weight under sealing condition, avoiding pollution.

- System includes frame, lifter, beam, collecting hopper, vibrator, gas-ballasting valve, connectors & plastic flexible pipes, etc.

- Transmitting under sealing condition, vacuum absorbing; open/closing angle of gas-ballasting valve and gas-ballasting time can be adjusted according to season and humidity.

- System design is capable for transmitting 1000kg~1500kg per hour.

5.2 Stuffing drying and transmitting system

- For transmitting stuffing from hopper to drying tank by vacuum pressure difference. System includes vacuum transmitter, vacuum pump, filter, vacuum drying tank, releasing valve, heater, etc.

- Vacuum drying tank has heating system, heat up to 125C; Inside tank there is horizontal stirring mixer.

- Dried stuffing will be fed into two storing & degassing tanks via screw transmitter mounted on the bottom of this vacuum drying tank.

- Stuffing feeding quantity to two degassing tanks are weighed and controlled by two electronic scales with digital displaying on both scale and industrial computer; Feeding quantity data can be saved and has power-off memory function.

5.3 300L resin mixing & degassing tank system

- This tank can mix, degas and store resin & stuffing, ready for being counted into accounting tank; Adopting film-degassing method.

- Tank effective volume 300L; Heat induction oil heating, share one 9kW electric heater with another counting tank, working temperature 60~80C.

- Adopting stainless steel anchor mixing method; Mixer is driven by a reducer on tope tank.

- Liquid material is added by high-viscosity diaphragm pump; Adding quantity is controlled by electronic scale self-equipped; Automatically finish material adding by preset parameter; Every proportion can be supervised and recorded; Material counting precision +/-1%.

- Ultimate vacuity under idle condition is 0.02mbar; vacuum leakage rate under idle condition (including pipeline) 0.05mbar. LS; Data is measured by imported vacuum transmitter.

- Tank mouth seal is made by material from America; Door open/close transmission section is our special design, life can be compared with any other competitors in the world.

- Tank door has one lighting-observing window.

5.4 300L hardener mixing & degassing tank system

- For mixing liquid type hardener and stuffing, then degassing and storing.

- Configurations are exactly same as above Item 4.3 for resin.

5.5 300L resin counting tank system

- This tank can mix and store materials fed into it and keep ready for timely casting. Counting pump is installed on side wall of tank. Optimized design makes no residual material.

- Effective volume 300L; Heat induction oil heating, share one 9kW electric heater with another counting tank, working temperature 60~80C.

- Adopting stainless steel anchor mixing method; Mixer is driven by a reducer on tope tank.

- Material feeding to this tank from mixing & degassing tank is by vacuum absorbing; Quantity is controlled by material leveler inside the tank. When material level reaches the top limit, stop absorbing; When material level reaches the bottom level, system alarm and start absorbing. The process is full automatic.

- Ultimate vacuity under idle condition is 0.02mbar; vacuum leakage rate under idle condition (including pipeline) 0.05mbar. LS; Data is measured by imported vacuum transmitter.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Industrial Vacuum Drying Oven Heating By Gas Burner For Transformer Drying

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Other, Natural Gas/LPG

Type : Other Ovens, Vacuum Drying Oven

Condition : New

Surface Finish : Other , Powder Coated / Painted

full automatic vacuum casting machine for epoxry resin dry-type transformers

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Power Source : Electric

Type : Other Ovens, Epoxy Resin Vacuum Casting Machine

Condition : New

Surface Finish : Other , Powder coated / sandblasted, corrosionresistant

Transformer Test System

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Type : Other Ovens, Industrial Transformer Test System

Condition : New

Surface Finish : Powder Coated

Dry-Type Transformer Vacuum Epoxy Resin Casting Plant

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Type : Other Ovens, Vacuum Epoxy Resin Casting Plant

Condition : New

Surface Finish : Other , Powder Coated / Painted

Send Inquiry

Send Inquiry