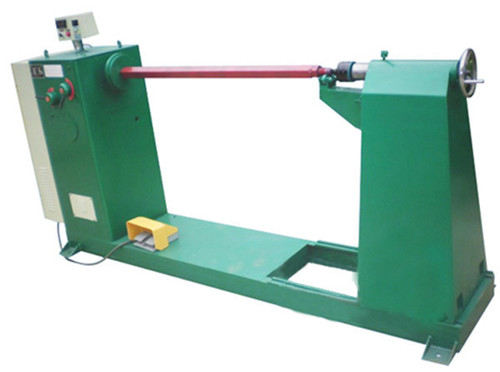

Traditional Coil Winding Machine

Price 10000 USD ($)/ Unit

Traditional Coil Winding Machine Specification

- Product Type

- Traditional Coil Winding Machine

- General Use

- Coil winding for electrical and transformer coils

- Material

- Cast Iron & Mild Steel

- Type

- Bench Type

- Weight (kg)

- Approx. 35 kg

- Computerized

- No

- Automatic

- No

- Control System

- Mechanical Lever

- Power Source

- Manual (Hand Operated)

- Coil Diameter

- Up to 150 mm

- Winding Head

- Single

- Winding Speed

- Depends on manual rotation (0-250 RPM approx.)

- Winding Spindle

- 1

- Drive Type

- Manual

- Dimension (L*W*H)

- Approx. 400 mm 250 mm 350 mm

- Feature

- Robust Construction, Easy Operation, Low Maintenance

- Color

- Green

- Lubrication

- Manual

- Operating Mode

- Hand Crank

- Counter

- Mechanical Stroke Counter

- Suitable For

- Copper and Aluminum Wire

- Application

- Transformer, Motor, Choke and Relay Coil Winding

- Base Type

- Table Mounted

- Wire Diameter Range

- 0.1 mm - 2.0 mm

- Noise Level

- Low

- Finish

- Powder Coated

- Maximum Coil Length

- Approx. 200 mm

Traditional Coil Winding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Traditional Coil Winding Machine

Traditional coil winding machine

Description

The coil winding machine mainly consists of machine base, gear box, tail supporter, winding shaft, and control switch, etc. This machine is suitable for coil winding of power transformers.

Main features

- Tail supporter movable for different size of coils

- Intelligent counter, the turning number can be preset

- Counting record and memorizing in case power off

| Model | LGR-1W | GDY-3W | GDY-5W | GDY-10W |

| Capacity | 1 | 3 | 5 | 10 |

| Speed(rpm) | 0-100 | 0-60 | 0-30 | 0-15 |

| Center height (mm) | 800 | 1100 | 1400 | 1400 |

| Center distance mm | 600-1400 | 800-2000 | 1500-2800 | 2000-3500 |

| Main power (KW) | 2.2 | 5.5 | 7.5 | 15 |

| Chuck diameter mm | 400 | 600 | 800 | 1000 |

| Chuck segment | 4 | 4 | 4 | 4 |

| Chuck T-slot | M12 | M20 | M20 | M20 |

| Machine base | 3x1.2x0.5 | 3.8x1.7x0.7 | 4.9x2x0.86 | 5x2.1x0.86 |

| Gross weight Kg | 800/900 | 1500/1600 | 2000/3000 | 5000/5500 |

| Tail stock moving mm | 0-150 | 0-150 | 0-150 | 0-150 |

| Winding shaft (mm) | 40*40*1400 | 70*70*2000 | 70*70*2800 | 70*70*3500 |

| Safety device | N/A | N/A | Infrared ray induction | Infrared ray induction |

Efficient Hand-Operated Winding

This bench-type coil winding machine uses a simple hand crank mechanism, allowing users to manually control the speed and tension while winding coils. The mechanical lever and stroke counter ensure winding accuracy for electrical and transformer coils, making it suitable for both copper and aluminum wire applications in professional setups.

Durable Construction for Reliable Performance

Constructed from cast iron and mild steel, this machine is built to withstand rigorous use. Its powder-coated finish protects against corrosion, while the sturdy table-mounted base ensures stability during operation. The robust design supports low maintenance requirements, offering longevity and consistent performance over time.

Versatile Applications for Multiple Industries

Perfect for winding a variety of coils including transformer, motor, choke, and relay coils this device is widely used by manufacturers, exporters, distributors, and traders throughout India. Its manual operation and adaptability for different wire diameters allow for versatility in various electrical and industrial environments.

FAQs of Traditional Coil Winding Machine:

Q: How does the hand crank operate on the Traditional Coil Winding Machine?

A: The hand crank allows the user to manually rotate the winding spindle, giving full control over the winding speed and tension. This enables precise winding of coils according to specific requirements without relying on automatic systems.Q: What types of wire can be used with this coil winding machine?

A: This machine is compatible with both copper and aluminum wires, accommodating diameters ranging from 0.1 mm to 2.0 mm. It is suitable for a wide variety of coil winding tasks in electrical applications.Q: When is manual lubrication required for this machine?

A: Manual lubrication should be performed periodically, depending on the frequency of usage. This ensures smooth operation and helps maintain the longevity of moving parts within the machine.Q: Where is this machine typically installed or used?

A: The winding machine is designed to be table-mounted, making it ideal for installation in workshops, manufacturing units, repair facilities, and other areas where electrical coil production and winding are performed.Q: What is the process of coil winding using this machine?

A: To wind a coil, simply set up the wire spool, secure the core on the spindle, and operate the hand crank while monitoring turns with the mechanical stroke counter. This process provides manual precision and control throughout each winding operation.Q: How does the mechanical stroke counter benefit users during coil winding?

A: The mechanical stroke counter tracks the number of rotations made during winding, enhancing operational accuracy and ensuring that the specified number of windings is achieved for different coil requirements.Q: What are the main advantages of using this traditional coil winding machine?

A: Key benefits include easy operation, low noise levels, robust and low-maintenance construction, and precise manual controlmaking it an ideal solution for custom coil winding in electrical manufacturing and repair industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

Double Layer Low Voltage Foil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : Blue & White

Automatic : Yes

Drive Type : Other, Servo Motor

Product Type : Low Voltage Foil Winding Machine

Automatic Coil Winding Machine With Auto Wire And Insulation Paper Arrangement

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : Blue & White

Automatic : Yes

Drive Type : Other, Servo Motor Driven

Product Type : Automatic Coil Winding Machine

Foil Winding Machine Professional In Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : Blue and White

Automatic : Yes

Drive Type : Other, Servo Motor

Product Type : Foil Winding Machine

Transformer Vertical Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : Blue & White

Automatic : Other, Automatic

Drive Type : Other, Servo Motor Driven

Product Type : Coil Winding Machine

Send Inquiry

Send Inquiry