Foil Winding Machine Professional In Transformer

Price 10000 USD ($)/ Unit

Foil Winding Machine Professional In Transformer Specification

- Product Type

- Foil Winding Machine

- General Use

- Transformer Foil Coil Winding

- Material

- Stainless Steel & Mild Steel

- Type

- Automatic Foil Winder

- Weight (kg)

- 3500-5200 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 8-15 kW

- Coil Diameter

- Max. 1200 mm

- Winding Head

- Single/Double (optional)

- Winding Speed

- 1-24 m/min

- Winding Spindle

- Hardened Steel

- Air Pressure

- 0.5 - 0.7 MPa

- Drive Type

- Servo Motor

- Voltage

- 380V / 415V

- Dimension (L*W*H)

- 5200 x 1800 x 2200 mm

- Feature

- High Precision, Stable Operation, User Friendly Interface

- Color

- Blue and White

- Max. Coil Width

- 1300 mm

- Decoiler Type

- Hydraulic or Pneumatic

- Foil Thickness Range

- 0.2-2.0 mm

- Noise Level

- 78 dB

- Tension Control

- Automatic

- HMI Display

- Touch Screen Panel

- Foil Width Range

- 30-1300 mm

- Insulation Material Supported

- DMD, NOMEX, Kraft Paper

- Max. Foil Weight

- 1500 kg

- Foil Material Supported

- Copper, Aluminium

- Edge Alignment Accuracy

- 0.2 mm

- Cutting System

- Automatic Shearing Device

Foil Winding Machine Professional In Transformer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Foil Winding Machine Professional In Transformer

Foil Winding Machine Professional In Transformer

Foil winding machine is suitable for foil winding of all types of small and medium sized distribution transformer, instrument transfo-Foil coil conductor is based on different thickness of copper or aluminum foil tape, with wide strip of insulating material for layer insulation, with narrow strip of insulating material for end insulation, winding the completion of the winding machine and roll into coil. At the same time, complete the coil of the lateral surface dressing. All kinds of functions of the equipment provides sufficient support for the production of foil coils that meet regulatory requirements.

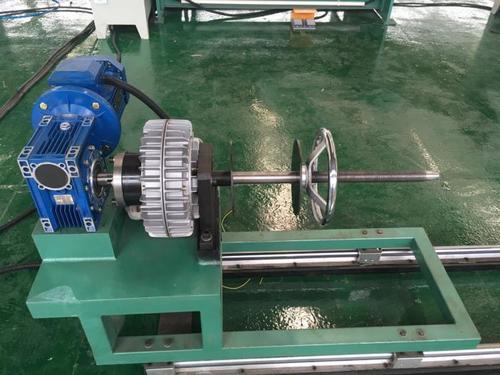

The foil winding machine mainly consists of decoiling, deburring, cleaning, correction centering, foil strip cutting, inter lamination insulationg filling, welding, recoiling and control system. The shape of the coil can be round, oval, rectangular, and square.

Technology parameters professional in transformer

| Model | BRJ-600 | BRJ-800 | BRJ-1000 | BRJ-1400 | BRJ-1600 |

| Width Of Foil Sheet mm | 200-800 | 200-1000 | 500-1400 | 500-1600 |

|

| Max Coil outer diameter mm | 800 | 800 | 1000 | 1000 |

|

| Foil thickness mm | 0.3-2.5mm 0.5-3.0mm | ||||

| Single or Double |

| ||||

| Winding speed r/min | 0-24 | 0-24 | 0-24 | 0-24 |

|

| Max.tension of foil N.M | 12000 | 16000 | 20000 | 25000 |

|

| End Insulation quantity | 8 or 12 disc | ||||

| Layer Insulation quantity | 2 | ||||

| Welding speed | 0-1m/min | ||||

| Correction precision | 0.5mm | ||||

| Welding method | TIG or Cold pressure welding | ||||

| Voltage V | AC380 | ||||

Advanced Control and Precision

Equipped with a PLC control system and a touch screen HMI, the machine allows for automated, precise winding with user-friendly operation. The automatic tension control and edge alignment features ensure each coil meets strict quality standards, making the machine ideal for producing transformer foil coils in bulk.

Versatile Material Support

This foil winding machine is compatible with copper, aluminium, and insulation materials like DMD, NOMEX, and Kraft Paper. It utilizes a hydraulic or pneumatic decoiler and an automatic shearing device, allowing for seamless integration with varied production requirements in transformer manufacturing.

Efficient Production and Safety

Operating at low noise levels (78 dB) and featuring high winding speeds (1-24 m/min), this machine boosts productivity while maintaining a safe working environment. Its robust build, comprising stainless and mild steel, ensures durability for heavy-duty industrial usage.

FAQs of Foil Winding Machine Professional In Transformer:

Q: How does the Foil Winding Machine maintain high edge alignment accuracy during operation?

A: The machine uses advanced sensors and servo motors, controlled by a PLC system, to continuously monitor and adjust foil position, ensuring edge alignment accuracy within 0.2 mm throughout the winding process.Q: What types of foil and insulation materials can be used with this machine?

A: The machine supports copper and aluminium foils with widths between 30 and 1300 mm and thicknesses from 0.2 to 2.0 mm. For insulation, DMD, NOMEX, and Kraft Paper are compatible, enhancing flexibility for different transformer winding requirements.Q: When is this machine commonly used in transformer manufacturing?

A: This automatic foil winding machine is typically utilized in the coil production stage, where precision and speed are essential for preparing transformer windings with consistent electrical and structural properties.Q: Where is the Foil Winding Machine manufactured and distributed?

A: The machine is produced, distributed, and exported by established Indian manufacturers, suppliers, and traders, serving clients both domestically and internationally in the transformer industry.Q: What is the process for changing between winding heads or foil materials?

A: Switching between single/double winding heads or different foil materials is streamlined via the touch screen HMI, hydraulic/pneumatic decoiler, and modular spindle design, allowing quick adaptation to various coil specifications.Q: How does automatic tension control benefit the winding process?

A: Automatic tension control ensures consistent pressure during winding, reducing material stress and improving coil quality by minimizing foil wrinkles or misalignment, thus enhancing overall process reliability.Q: What advantages does using this machine offer for transformer coil production?

A: Operators benefit from high precision, stable operation, reduced manual intervention, and efficient use of materials. The user-friendly interface, computerized controls, and automated features lead to consistent transformer coil quality and increased productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

Horizontal Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380V / 415V 3 Phase

Automatic : Yes

Winding Head : Other, Single/Double as per requirement

Winding Speed : Up to 600 RPM

High Voltage Automatic Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220/380V, 50Hz/60Hz

Automatic : Yes

Winding Head : Other, Single/Double (Optional)

Winding Speed : Max 1200 RPM

Automatic 3D Triangle Wound Core Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380V / 415V, 50/60Hz

Automatic : Yes

Winding Head : Other, Single / Triple

Winding Speed : Max 120 RPM

Foil Winding Machine Professional In Reactor

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 415V, 3 Phase, 50 Hz

Automatic : Other, Fully Automatic Operation

Winding Head : Other, DualHead System

Winding Speed : 215 m/min Adjustable

Send Inquiry

Send Inquiry