VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation

Price 10000 USD ($)/ Unit

VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation Specification

- Condition

- New

- Heating Method

- Electric Heating (Optional Thermic Fluid/Oil)

- Power Source

- Electric

- Accuracy

- 1C (temperature control)

- Control Mode

- PLC / Manual

- Heating Capacity

- Customized (Typically up to 120C)

- Type

- Vacuum Pressure Impregnation System

- Model

- VPI 1600-3000

- Internal Size

- Dia 1600 mm x 3000 mm

- External Size

- Approx. Dia 1700 mm x 3200 mm

- Volume

- Approx. 6.0 m

- Air Flow

- Not Applicable (Vacuum System)

- Temperature Range

- Ambient to 120C

- Material

- Mild Steel / SS 304

- Dimension (L*W*H)

- Approx. 3700 x 1700 x 1900 mm

- Power

- 8-15 kW (Depending on configuration)

- Voltage

- 380-415V/3 Phase/50 Hz

- Surface Finish

- Painted/Anti-corrosive epoxy coated

- Safety Features

- Pressure relief valve, interlocks, emergency stop

- Chamber Shape

- Horizontal Cylindrical

- Impregnation Cycle

- Programmable cycles

- Application

- Traction motors, transformer cores, windings

- Control Panel

- Digital/PLC with HMI interface

- Vacuum Level

- Up to 1 mbar (Abs)

- Resin Handling

- Automated/Manual Dosing

- End Closure

- Hydraulic Quick Opening Door

- Compliance Standards

- As per IS/IEC Standards

- Working Pressure

- Up to 7 bar

VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

About VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation

General Introduction

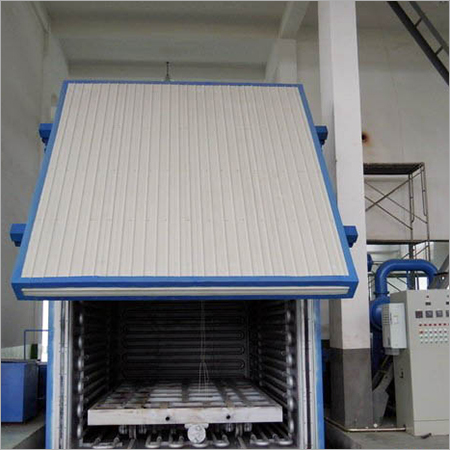

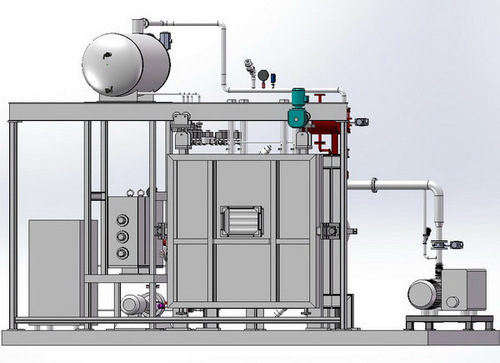

The VPI system is used for impregnating of elements of electrical motors, and also can be used for impregnating of reactor, power transformer, etc. The insulation class can be up to H class. This VPI system is designed and made as per customer's requirements.

Advanced Vacuum Pressure Impregnation Technology

This VPI System utilizes powerful vacuum and pressure cycles to drive impregnating resin deep into motor windings and transformer cores. Its programmable controls and automated resin handling deliver consistent, high-quality results for a range of industrial needs, enhancing insulation and lifecycle of electrical components.

Safety and Precision at the Core

Safety features such as pressure relief valves, interlocks, and an emergency stop ensure operator security during every cycle. The PLC/HMI interface allows precise monitoring and control, while temperature is maintained within 1C, critical for sensitive resin processing.

Compliant, Versatile, and Durable

This system is meticulously engineered to meet IS/IEC standards. With a horizontal cylindrical chamber and durable construction, it is ideal for both small and large-scale production environments across manufacturers, exporters, and distributors.

FAQs of VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation:

Q: How does the VPI 1600-3000 system enhance insulation quality?

A: By using high vacuum (down to 1 mbar abs) and controlled pressure cycles up to 7 bar, the system deeply impregnates windings and transformer cores with resin. This eliminates air pockets and voids, dramatically enhancing insulation integrity and reliability of electrical components.Q: What is the typical process cycle for resin vacuum pressure impregnation?

A: The impregnation cycle starts by placing components inside the chamber, pulling a deep vacuum to remove air, introducing resin (automatically or manually), then applying pressure to force resin thoroughly into the windings. The systems PLC can be programmed for different cycle parameters, ensuring repeatable results.Q: When should the VPI system be used in electrical manufacturing?

A: Its ideal during the final production stages of motors, transformer cores, or windings after component assembly but before final testing or enclosure, ensuring optimal insulation and extended service life.Q: Where can this system be installed and operated?

A: Designed for versatility, the system can be installed in manufacturing plants, repair workshops, or testing centers. Its standard power requirements (380-415V, 3-phase, 50 Hz) and robust construction suit a variety of industrial environments.Q: What benefits does automated resin handling provide?

A: Automated dosing improves process consistency, reduces manual labor, and minimizes resin waste. It ensures accurate resin quantity for each cycle, lowering human error and increasing throughput.Q: What safety features are integrated into the VPI 1600-3000 system?

A: Safety is addressed with a hydraulic quick opening door, pressure relief valves, safety interlocks, and emergency stop functions, protecting both operator and equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Kerosene vapor-phase drying equipment

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Control Mode : PLC/Automatic Control

Heating Capacity : Up to 5000 kg/batch (customizable)

Model : KVPDSeries

Dimension (L*W*H) : Customized

HS-300A Automatic Vacuum Casting Machine Dynamic Material Mixing

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Control Mode : PLC Automatic Control

Heating Capacity : 300C max

Model : HS300A

Dimension (L*W*H) : 1020 800 1800 mm

Transformer Vacuum Oil-filling equipment

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Control Mode : Automatic PLC Control

Heating Capacity : 80 kW

Model : TVOF80

Dimension (L*W*H) : 1800 mm x 1200 mm x 1600 mm

Vacuum transformer oil purifier

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Control Mode : Automatic/Manual

Heating Capacity : 45 kW

Model : ZJA10

Dimension (L*W*H) : 1800 mm x 1200 mm x 1900 mm

Send Inquiry

Send Inquiry