High Voltage Foil Winding Machine For Transformer Production

Price 10000 USD ($)/ Unit

High Voltage Foil Winding Machine For Transformer Production Specification

- Product Type

- High Voltage Foil Winding Machine

- General Use

- For Transformer Coil Winding

- Material

- Stainless Steel & Alloy Components

- Type

- Fully Automatic Foil Winder

- Weight (kg)

- Around 2800

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Automatic Control

- Power Source

- 3 Phase Electric

- Power Consumption

- 8-11 KW

- Coil Diameter

- Max 1200 mm

- Winding Head

- Single / Double (Optional)

- Winding Speed

- Up to 30 m/min

- Winding Spindle

- Heavy Duty Precision Spindle

- Air Pressure

- 0.6-0.8 MPa

- Drive Type

- Servo Motor

- Voltage

- 380/415V

- Dimension (L*W*H)

- 4200 x 1800 x 2200 mm

- Feature

- High Precision Winding, Fault Detection, Touchscreen Interface

- Color

- Industrial Blue & Silver

- Edge Alignment Accuracy

- 0.2 mm

- Operator Interface

- HMI Touch Panel

- Insulation Layer

- Automatic interlayer paper feeder

- Main Function

- Layer insulation, edge folding, foil cutting, and stacking

- Ambient Temperature

- 5C 40C

- Welding System

- Integrated TIG/Cold Pressure Welding

- Decoiler Capacity

- Up to 2 Tons

- Operating Mode

- Manual/Automatic Selection

- Safety Features

- Emergency stop, protective hood, automatic fault alarm

- Max Foil Width

- 600 mm

- Applicable Foil Types

- Copper & Aluminum Foil

- Production Output

- Suitable for medium to large transformer manufacturing plants

- Noise Level

- 75 dB

- Foil Thickness Range

- 0.2 3.0 mm

High Voltage Foil Winding Machine For Transformer Production Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About High Voltage Foil Winding Machine For Transformer Production

HIGH VOLTAGE FOIL WINDING MACHINE

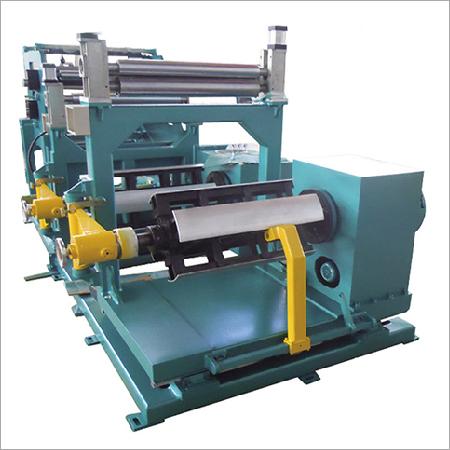

Description: This High Voltage Foil Winding Machine is suitable for 1KV and more than 1KV level transformer windings. All the production parameters are set on the Human-Computer Interface and the machine works in fully automatic.

Main machine components:

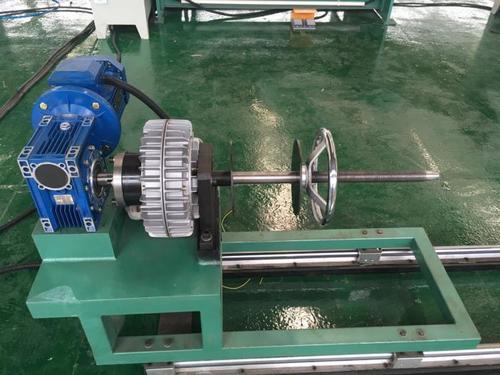

- VF controlling stepless speed foil winding unit

- DC motor driven conductor decoiling unit

- DC motor driven double insulation decoiling unit

- Servo controlling AC/DC water-cooling TIG welding unit

- PLC controlling and touch screen operation system

Specification:

| Foil | Insulation | Winding | |||

| Item | Value | Item | Value | Item | Value |

| Foil width | 20-200mm | Insulation width | 25-250mm | Winding width | 20-1400mm |

| Copper thickness | 0.1-2.5mm | Thickness | 0.015-0.250mm | Tension | 0-10N/mm2 |

| Al thickness | 0.2-3.0mm | Tension | 10-250N | Winding diameter | 100-1000mm |

| Tension | 50-3000N | Expand shaft | 74-78mm | Winding weight | Max:1000KG |

| Decoiler diameter | 280-330mm | Insulation outer diameter | 400mm | Torque | Max:1800N.M |

| Foil outer diameter | Max 1000mm |

|

| Winding speed | 90r/min |

| Foil weight | Max 1000KG |

|

| Motor power | 18.5KW |

Precision and Versatility for Transformer Coil Production

This foil winding machine delivers high precision with edge alignment accuracy of 0.2 mm and a winding speed of up to 30 m/min. It can handle a wide range of foil dimensions and types, including copper and aluminum, making it ideal for various transformer designs. The integrated insulation feeder and welding systems significantly streamline the coil assembly process.

Automated Operation for Maximum Productivity

With fully automatic PLC control and a user-friendly HMI touchscreen panel, operators can easily switch between manual and automatic modes. The decoiler can handle up to 2 tons, supporting continuous production. Fault detection, emergency stops, and protective hoods are incorporated for safety and reliability, while noise levels remain comfortably below 75 dB.

Adaptable to Industry Needs

Suitable for medium to large transformer manufacturing plants, the machines single or double winding head and high winding speed enable adaptability in different production environments. Constructed from stainless steel and alloy components, it guarantees durability and stable operation under varying ambient temperatures and air pressures.

FAQs of High Voltage Foil Winding Machine For Transformer Production:

Q: How does the High Voltage Foil Winding Machine improve transformer coil production efficiency?

A: By automating layer insulation, edge folding, foil cutting, and stacking, this machine shortens production cycles and enhances accuracy. The integrated TIG and cold pressure welding systems further ensure consistent coil quality and minimal human error.Q: What types of foils can be processed with this winding machine?

A: It is designed to work with both copper and aluminum foils with widths up to 600 mm and thicknesses ranging from 0.2 to 3.0 mm, making it suitable for various transformer applications.Q: When should manual or automatic operation modes be used?

A: Automatic mode is ideal for high-volume or repetitive coil production, maximizing speed and consistency. Manual mode is recommended for special winding requirements, maintenance, or specific adjustments during set-up.Q: Where can this machine be installed and operated?

A: This machine is best suited for medium to large transformer manufacturing facilities. It operates efficiently within an ambient temperature range of 5C to 40C and requires a 3-phase electric power source.Q: What is the process for feeding insulation layers and aligning edges?

A: Insulation paper is automatically fed between foil layers, while advanced servo motor control maintains edge alignment at 0.2 mm accuracy throughout the winding process, ensuring precise and reliable coil production.Q: What are the benefits of its PLC automatic control system?

A: The PLC system automates complex winding parameters, enables real-time fault detection, and simplifies operation through the HMI touchscreen interface, improving user experience, consistency, and overall productivity.Q: How does the machine ensure operator safety during operation?

A: Safety features include emergency stop buttons, protective hoods, and automatic fault alarms, minimizing risks and ensuring safe day-to-day operation for all personnel involved.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

Automatic 3D Triangle Wound Core Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 15001800 kg

Material : Other, Stainless Steel / Mild Steel

Power Source : Electric

Winding Head : Other, Single / Triple

Foil Winding Machine Professional In Reactor

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 2600 kg

Material : Other, Mild Steel Frame, Aluminum and Stainless Steel Parts

Power Source : Electric

Winding Head : Other, DualHead System

Horizontal Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 18002500 kg

Material : Other, Mild Steel and Alloy Components

Power Source : Electric

Winding Head : Other, Single/Double as per requirement

3d Foil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1500 kg

Material : Other, Steel, Hardened Alloys

Power Source : Other, AC Electric

Winding Head : Other, 3D Articulating Winding Head

Send Inquiry

Send Inquiry