High Voltage Foil Winding Machine For Transformer Production

Price 10000 USD ($)/ Unit

High Voltage Foil Winding Machine For Transformer Production Specification

- Product Type

- High Voltage Foil Winding Machine

- General Use

- Transformer Foil Coil Winding

- Material

- Copper/Aluminum Foil

- Type

- Automatic Winding Machine

- Weight (kg)

- Approx. 4000-5000 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC with Touch Screen Interface

- Power Source

- Three Phase Electric

- Power Consumption

- 8-15 kW

- Coil Diameter

- Max. 1200 mm

- Winding Head

- Single/Double (customizable)

- Winding Speed

- 0-25 m/min (adjustable)

- Winding Spindle

- Heavy Duty Precision Spindle

- Air Pressure

- 0.5-0.7 MPa

- Drive Type

- Servo Motor Driven

- Voltage

- 380 V / 415 V

- Dimension (L*W*H)

- 4500 2000 2200 mm

- Feature

- Automatic Tension Control, Precise Foil Alignment

- Color

- Blue & Grey

- Edge Alignment Accuracy

- ±0.5 mm

- Slitting System

- Included for Foil & Insulation

- Safety Features

- Emergency Stop, Overload Protection

- Operator Interface

- Multi-language Touch Panel

- Foil Width Range

- 100-1200 mm

- Layer Insulation Station

- Integrated with Automated Cutting

- Application

- Power & Distribution Transformer Manufacturing

- Noise Level

- <75 dB(A)

- Unwinding and Rewinding

- Hydraulic Expandable Chucks

- Thickness of Foil

- 0.2-3.0 mm

High Voltage Foil Winding Machine For Transformer Production Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About High Voltage Foil Winding Machine For Transformer Production

High Voltage Foil Winding Machine

Description: This High Voltage Foil Winding Machine is suitable for 1KV and more than 1KV level transformer windings. All the production parameters are set on the Human-Computer Interface and the machine works in fully automatic.

Main machine components:

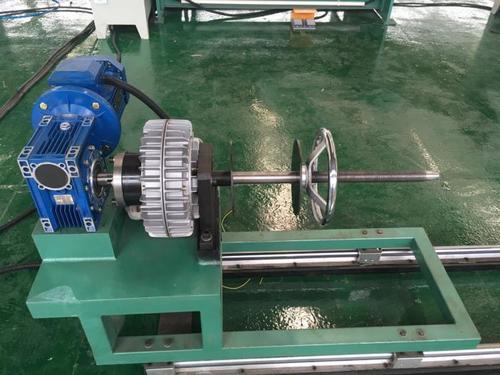

- VF controlling stepless speed foil winding unit

- DC motor driven conductor decoiling unit

- DC motor driven double insulation decoiling unit

- Servo controlling AC/DC water-cooling TIG welding unit

- PLC controlling and touch screen operation system

Cutting-Edge Automation for Transformer Production

This foil winding machine brings advanced automation to transformer manufacturing, featuring a multi-language touch panel, servo-driven winding, and integrated insulation cutting and slitting. With automatic tension control and precise foil alignment, operators achieve consistent, high-quality coils for both power and distribution transformers.

Robust Design and Flexible Operation

Engineered for heavy-duty use, the machine accommodates copper and aluminum foils and supports a coil diameter up to 1200 mm. Hydraulic expandable chucks and precision spindles ensure stable unwinding and rewinding. Its blue-and-grey frame combines durability with aesthetic appeal.

Safety and User Experience First

Safety is paramount, with emergency stop and overload protection built into the control system. The touch-screen PLC ensures easy parameter setup and real-time monitoring in multiple languages. Low noise emissions (<75 dB(A)) and ergonomic controls reduce operator fatigue and ensure a comfortable working environment.

FAQs of High Voltage Foil Winding Machine For Transformer Production:

Q: How does this foil winding machine maintain precise edge alignment during operation?

A: The machine leverages servo motor-driven controls and an integrated edge alignment system to maintain a high degree of precision, achieving an accuracy of 0.5 mm throughout the winding process. This ensures uniform windings and reduces material wastage.Q: What types of transformers can be manufactured using this machine?

A: This automatic foil winding machine is suitable for the production of both power and distribution transformers, making it ideal for manufacturers and suppliers involved in large-scale transformer manufacturing projects.Q: When should the integrated automated insulation cutting system be utilized?

A: The automated insulation cutting system operates during the winding process, enabling layer insulation to be added precisely between foil layers without manual intervention. This streamlines production and minimizes errors during multi-layer coil fabrication.Q: Where is this machine typically installed and operated?

A: Designed for industrial environments, the machine is commonly found in transformer manufacturing plants and workshops, particularly at distributor, exporter, manufacturer, and supplier facilities across India and internationally.Q: What is the main process flow of the high voltage foil winding machine?

A: The process involves unwinding copper or aluminum foil via hydraulic chucks, feeding it through the slitting system for precise width and insulation application, winding the foil around a spindle to form coils, and then rewinding finished coils. All steps are controlled and monitored through the PLC touch screen interface.Q: How does the automatic tension control benefit production quality?

A: Automatic tension control prevents slack or over-tightening of foil during winding. This maintains consistent coil density, minimizes damage, and ensures high-quality final products, meeting stringent electrical and mechanical requirements for transformers.Q: What are the advantages of the PLC touch screen interface with multi-language support?

A: The PLC touch screen allows operators to parameterize settings, monitor processes, and address faults with ease. Multi-language capability ensures usability for a diverse workforce, reducing training time and enhancing operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

High Voltage Automatic Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Yes

Drive Type : Other, Servo Motor

Feature : Other, High Precision, Programmable, Stable Performance

Automatic 3D Triangle Wound Core Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Yes

Drive Type : Other, Servo Motor

Feature : Other, Energy Efficient, High Precision Winding, UserFriendly Operation

High Voltage Coil Winding Machine With Auto Wire And Paper Arrangement

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Other, Fully Automatic

Drive Type : Other, Servo Motor Drive

Feature : Other, Automatic Wire & Paper Arrangement, Wire Tension Control, Programmable Layering

25T Vertical Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic : Other, Fully Automatic

Drive Type : Other, Electric & Servo Motor Driven

Feature : Other, Heavy Load Capacity, High Precision Winding, Digital Controls

Send Inquiry

Send Inquiry