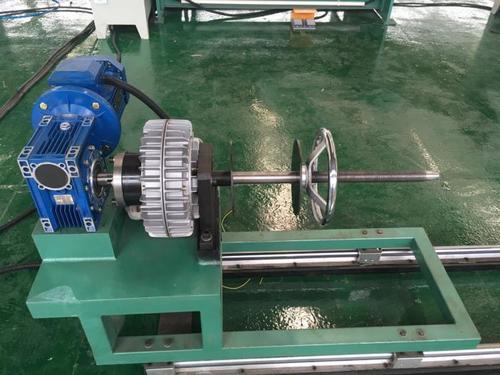

Transformer Horizontal Coil Winding Machine

Price 10000 USD ($)/ Unit

Transformer Horizontal Coil Winding Machine Specification

- Product Type

- Coil Winding Machine

- General Use

- Transformer Coil Winding

- Material

- Mild Steel

- Type

- Horizontal

- Weight (kg)

- 1200

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Controlled

- Power Source

- Electric

- Power Consumption

- 4 kW

- Coil Diameter

- Max 1200 mm

- Winding Head

- Single/Double Head

- Winding Speed

- 0-180 rpm (Adjustable)

- Winding Spindle

- Heavy Duty High Precision

- Air Pressure

- 6-8 bar

- Drive Type

- Servo Motor

- Voltage

- 380 V / 440 V, 3 Phase

- Dimension (L*W*H)

- 2800 x 1250 x 1400 mm

- Feature

- High Performance, Robust Construction, Easy Operation

- Color

- Blue & White

- Safety Mechanism

- Emergency Stop, Overload Protection

- Winding Program Storage

- Up to 100 Programs

- Max Load Capacity

- 1000 kg

- Max Coil Width

- 500 mm

- Display

- Digital Touch Screen

- Wire Size Range

- 0.2 mm - 4.0 mm

- Cooling System

- Air Cooled

- Application

- Distribution & Power Transformer Coils

- Noise Level

- < 75 dB

Transformer Horizontal Coil Winding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Transformer Horizontal Coil Winding Machine

This series of winding machine is widely used in oil-immersed transformers, dry-type transformers, special transformers, reactor production.

Main Features:

- Winding with a continuous tension and the tension size is given in the control pane. The device winding back or stop still maintain tension to ensure that the coil tight. The electronic counter has automatic counting and power-off memory function.

- The motor adopts frequency conversion speed control, which is controlled by the inverter, so the starting and braking probability can be made to adapt to the best state of winding. Frequency conversion speed regulation is wide, accurate and stable

- The whole structure is welded by steel plate, and the stability is higher than other brands.

- This machine adopts hardened cylindrical gear mechanical variable speed system, it enjoys low noise and high efficiency.

- Control box is placed in the top of the chassis and it's easy to use and display

Technology parameters

| Items | Model | ||||||

| WRJ-0.5T | WRJ-1T | WRJ-2T | WRJ-3T | WRJ-5T | WRJ-10T | ||

| Max.loading | 0.5T | 1T | 2T | 3T | 5T | 10T | |

| Main axis rotating speed r/min | 0-200 | 0-150 | 0-60 | 0-20 | 0-10 |

| |

| Main axis center height mm | 950 | 950 | 1100 | 1300 | 1400 |

| |

| Max.distance between Main axis and end seat mm | 1500 | 1500 | 2500 | 3000 | 3500 |

| |

| End seat moving stroke mm | 0-750 | 0-1000 | 0-1200 | 0-1500 | 0-1500 |

| |

| Main axis power KW | 4 | 5.5 | 7.5 | 11 | 15 |

| |

| Voltage V | AC380 | ||||||

Efficient Transformer Coil Production

Designed for high-performance coil winding, this machine improves productivity and reduces operational time for transformer manufacturers. With computerized automation, robust construction, and intuitive controls, users can handle large coil diameters up to 1200 mm with precision and safety.

Advanced Control and Safety Features

Equipped with a PLC-controlled system and digital touch screen, the machine offers programmable flexibility for up to 100 winding setups. Integrated safety mechanisms such as emergency stop, overload protection, and air-cooled systems contribute to consistent and secure operation in production environments.

Versatile Application and Reliable Build

Suitable for winding coils in both distribution and power transformers, this horizontal winding machine is built from high-grade mild steel for durability. Its heavy-duty high-precision spindle ensures stable operation, while adjustable winding speed accommodates a broad range of coil specifications.

FAQs of Transformer Horizontal Coil Winding Machine:

Q: How does the coil winding process work on this machine?

A: The coil winding process utilizes a servo motor-driven spindle, which guides wire of 0.2 mm to 4.0 mm size onto the coil with programmable precision. Operators select their winding program via the digital touch screen, and the machine automatically executes the process according to stored parameters.Q: What are the key safety mechanisms integrated in the machine?

A: The machine is equipped with emergency stop buttons, overload protection, and an air-cooled system. These features ensure operator safety and protect internal components during intensive or prolonged coil winding sessions.Q: Where is this horizontal coil winding machine primarily used?

A: It is mainly utilized in transformer manufacturing plants across India and globally, catering to distribution and power transformer coil production. Manufacturers, distributors, exporters, and suppliers benefit from its high efficiency and reliability.Q: When should the winding speed be adjusted, and what range is available?

A: Winding speed should be tailored based on wire type and coil specifications. The machine provides an adjustable speed range from 0 to 180 rpm, allowing operators to optimize processing time without compromising coil quality.Q: What are the benefits of a PLC-controlled and computerized winding system?

A: A PLC-controlled, computerized system enables precise automation, storage of up to 100 winding programs, and quick changeovers. This increases production flexibility, reduces manual intervention, and improves quality consistency across batches.Q: How does the air-cooled system contribute to machine performance?

A: The air-cooled system maintains optimal operating temperatures for the winding process, ensuring stable performance. It prevents overheating during long-duration operations, which enhances machine lifespan and reduces maintenance requirements.Q: What measures ensure accuracy and durability during coil winding?

A: Accuracy is achieved with heavy-duty, high-precision winding spindles and servo motor drive. Mild steel construction and robust design safeguard against wear, while precision controls guarantee consistently wound coils, maximizing production quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

Transformer Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

General Use : For Winding Transformer Coils

Voltage : 220240V, 50Hz (Single Phase)

Material : Other, Mild Steel (MS)

Computerized : No

Foil Winding Machine Professional In Reactor

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

General Use : Reactor Coil & Transformer Coil Winding

Voltage : 380V / 415V, 3 Phase

Material : Other, Mild Steel / Stainless Steel / Aluminum parts

Computerized : Yes

Automatic 3D Triangle Wound Core Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

General Use : Transformer Coil Manufacturing

Voltage : 380V / 415V, 50/60Hz

Material : Other, Stainless Steel / Mild Steel

Computerized : Yes

Horizontal Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial Coil Winding

Voltage : 380V / 415V 3 Phase

Material : Other, Mild Steel and Alloy Components

Computerized : Yes

Send Inquiry

Send Inquiry