Stepping transformer core cutting machine and automatic stacker

Price 10000 USD ($)/ Unit

Stepping transformer core cutting machine and automatic stacker Specification

- Product Type

- Stepping transformer core cutting machine with automatic stacker

- General Use

- Used for cutting and stacking transformer laminations

- Material

- High grade alloy and stainless steel

- Type

- Automatic

- Weight (kg)

- 2300 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC based touch screen control

- Power Source

- Electric

- Power Consumption

- 5.5 kW

- Air Pressure

- 0.5 - 0.7 MPa

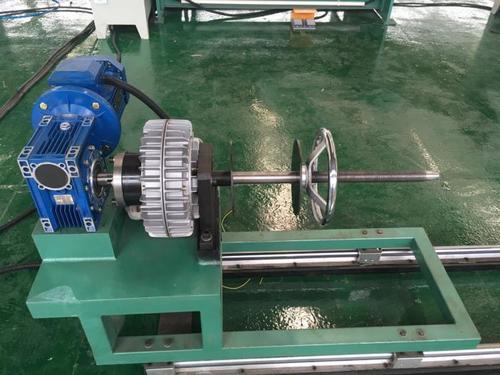

- Drive Type

- Servo motor and pneumatic drive

- Voltage

- 380V / 50Hz

- Dimension (L*W*H)

- 3400 mm x 1800 mm x 1700 mm

- Feature

- High precision, fast operation, auto stacking, minimal wastage

- Color

- Industrial Grey

- Safety Features

- Emergency stop, interlock doors, overload protection

- Operator Interface

- Touchscreen HMI panel

- Noise Level

- <72 dB(A)

- Stacking Height Range

- up to 600 mm

- Feeding System

- Servo feed with rotary encoder feedback

- Production Capacity

- 25-30 pieces/min (depends on core size and material)

- Stacking Modes

- Step lap, multi-step, straight stacking

- No. of Cutting Heads

- 1 (standard), configurable

- Cutting Thickness Range

- 0.2-0.5 mm (lamination sheet)

- Compressed Air Consumption

- 0.3 m³/min

- Blade Type

- Hardened carbide, quick-change

- Cutting Accuracy

- ±0.2 mm

- Cutting Length Range

- 50 mm to 9999 mm

- Operating Temperature

- 5°C to 40°C

Stepping transformer core cutting machine and automatic stacker Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 60 Days

About Stepping transformer core cutting machine and automatic stacker

- Step-lap transformer core cut to length machine is specially designed for cutting silicon steel coils into lamination strips used in transformer cores.

- Step-lap transformer core cut to length machine adopts swing shear cutting device which is similar to Georg swing shear cutting machine.

- Step-lap transformer core cut to length machine is a very small machine, main body is only about 2.2m long, including centering, notching, punching and cutting.

- Step-lap transformer core cut to length machine combines V-notching, hole-punching and mitre cutting togther, high automation, high efficiency. Usually one 8-hour shift can cut 1 ton lamination strips.

- Step-lap transformer core cut to length machine adopts Delta PLC, touch screen (HMI), inverter, servo motor and drive, high precision, good after-sale service.

- Step-lap transformer core cut to length machine adopts special carbide alloy for cutting blade and notching blade and punching tools as well. Life can be more than 2,000,000 times before grinding and more than 20 times grinds.

Efficient and Accurate Lamination Cutting

This machine ensures consistently precise cuts for transformer core laminations, handling thicknesses between 0.2 and 0.5 mm with an outstanding cutting accuracy of 0.2 mm. Whether you need step lap, multi-step, or straight stacking, the advanced servo feed system with rotary encoder feedback guarantees seamless operation and minimal wastage, making it a reliable choice for manufacturers.

User-Friendly Control & Safety Focused

The PLC-based touchscreen HMI panel allows operators to intuitively set parameters, monitor progress, and swiftly make adjustments. Integrated safety features, such as emergency stop, interlock doors, and overload protection, provide a secure work environment while maintaining productivity and efficiency in demanding settings.

Designed for Industrial Demands

Built from high-grade alloy and stainless steel, this automatic machine boasts a substantial weight of 2300 kg, reflecting its durability. Quick-change carbide blades and minimized noise levels (<72 dB[A]) ensure smooth, uninterrupted production, making it well-suited for transformer manufacturers and suppliers seeking both speed and reliability.

FAQs of Stepping transformer core cutting machine and automatic stacker:

Q: How does the stepping transformer core cutting machine achieve high cutting accuracy?

A: The machine uses a servo feed system coupled with rotary encoder feedback, ensuring each lamination is cut within a tight tolerance of 0.2 mm. This precision is maintained throughout the operating range of 0.20.5 mm thickness and lengths up to 9999 mm.Q: What materials can be processed with this core cutting machine and stacker?

A: It is designed to process transformer lamination sheets made of high-grade alloy and stainless steel within the specified thickness range, ensuring suitability for heavy-duty industrial applications.Q: When is it beneficial to use the automatic stacker feature?

A: The automatic stacker is especially beneficial when processing large batches or when consistent, high stacking heights (up to 600 mm) are required. It streamlines the workflow by reducing manual handling and maintains accuracy across multiple stacking modes.Q: Where is this machine best utilized?

A: This equipment is ideal for transformer manufacturing plants, metalworking facilities, and assembly lines requiring precise cutting and automated stacking of transformer laminations. Its robust build and safety features make it suitable for intensive industrial environments.Q: What is the process for changing cutting blade types?

A: Blades are engineered for quick change. Operators can safely replace the hardened carbide blades using the integrated quick-change mechanism, minimizing downtime and ensuring continued production efficiency.Q: How does the operator interface enhance usability?

A: The PLC-based touchscreen HMI panel provides an intuitive interface for operators to set parameters, monitor real-time production, and swiftly address adjustments or errors, ensuring smooth and efficient operations.Q: What are the main benefits of using this automatic core cutting machine?

A: Key benefits include high-precision cutting, versatile stacking options, minimal material wastage, rapid operation (2530 pieces/min), enhanced safety, and user-friendly controlsall contributing to increased productivity and reduced operational costs for the manufacturer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Winding Machine Category

Foil Winding Machine Professional In Reactor

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Servo / Electric

Control System : PLC Based Control System

Automatic : Yes

Winding Spindle : Other, High Precision Steel

High Voltage Foil Winding Machine For Transformer Production

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Servo Motor

Control System : PLC Automatic Control

Automatic : Yes

Winding Spindle : Other, Heavy Duty Precision Spindle

Automatic 3D Triangle Wound Core Coil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Servo Motor

Control System : PLC with Touch Screen Interface

Automatic : Yes

Winding Spindle : Other, Hardened Alloy Steel

Double Layer Low Voltage Foil Winding Machine

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Servo Motor Drive

Control System : PLC Controlled with Touch Screen Interface

Automatic : Other, Fully Automatic

Winding Spindle : Other, Heavy Duty Precision Spindle

Send Inquiry

Send Inquiry