VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation

Price 10000 USD ($)/ Unit

VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation Specification

- Accuracy

- 1C (temperature control)

- Condition

- New

- Heating Method

- Electrical/Steam (Optional)

- Heating Capacity

- Customizable as per requirements

- Control Mode

- Automatic PLC Control

- Power Source

- Electric

- Type

- Vacuum Pressure Impregnation (VPI) System

- Model

- VPI-1600x3000

- Internal Size

- Approx. Dia 1550 mm x Length 2950 mm

- External Size

- Dia 1600 mm x Length 3000 mm

- Volume

- Approx. 5.65 m

- Air Flow

- Sealed Vacuum Chamber (No air flow)

- Temperature Range

- Ambient to 130C

- Material

- Mild Steel or Stainless Steel

- Dimension (L*W*H)

- Approx. 3800 x 2200 x 2200 mm

- Power

- 18~36 kW

- Voltage

- 380/415 V

- Surface Finish

- Paint Coated/Polished

- Safety Features

- Mechanical and electrical interlocks

- Application

- For resin impregnation of electrical components and rotating machinery

- Vacuum Level

- up to 0.1 mbar

- Operation

- Fully automated cycle management

- Door Type

- Flanged heavy-duty with hydraulic locking

- Chamber Construction

- Seamless welded for leak-proof operation

- Cycle Time

- Adjustable depending on material and resin

- Design Pressure

- 4~8 bar (customizable)

- Noise Level

- < 65 dB(A)

- Pump Type

- Rotary vane/Roots vacuum pump

- Resin Tank Capacity

- Customized as per user requirements

- Monitoring

- Digital temperature, pressure and vacuum gauges

- Installation Type

- Floor Mounted

VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

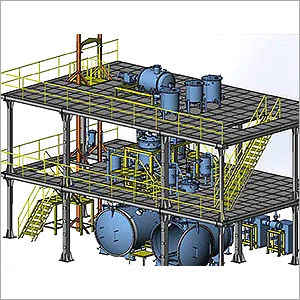

About VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation

The VPI system is used for impregnating of elements of electrical motors, and also can be used for impregnating of reactor, power transformer, etc. The insulation class can be up to H class. This VPI system is designed and made as per customer's requirements.

Machine Component Specification

3.1 Vacuum pressure impregnating tank

- Effective size: 1600x3000mm, vertical type, Q345R carbon steel 50Pa.L/s

- Working temperature: normal temperature ~ +80C

- VPI tank capacity: max. 35 ton

- Hydraulic open & lock for doors , with safety locking device

- Resin material feeding from the bottom, automatic stopping when match the level

- Configured with one set of liqidometer

- VPI basket diameter 1400mm x 2800mm, used for loading and unloading product, loading capacity is min.20 ton.

- Safety cock for the door

- 6 core vacuum sealed electrode connector for capacitance connecting

- 9 core vacuum sealed electrode connector for internal temperature measuring

- Effective size: 1400x3000mm, vertical type, Q235 carbon steel 100Pa.L/s

- Working pressure: vacuum degree normal pressure

- Working Vacuum: 100 - 1000 Pa

- Cooling system for the tank

- 50mm rock wool and stainless plate covered on the outside for heat preservation

- Multilayer impeller mixing, speed 30rpm

- Storage tank capacity: about 4600L

- Vacuum pump: Leybold brand for Fore Pump (Rotary Pump), SV-300B, Shanghai Sunny brand for Roots pump.

- Components: manual vacuum main valve, electrical tape charging valve, filter, vacuum meter, pipelines, valves, etc

- Automatic running PC-3 cooling water system, used for cooling for storage tank and condensator

- Configured with heat exchanger, pump, pipes, filter, etc.

- Max. pressure 16Mpa, working pressure 10Mpa

- Used for the open and locking for the tank door

- Components: valves, pipeline, filter, etc

- Configured with high precision filters, precision up to 150

- Integrated controlling cabinet mainly consists of industrial computer, Mitsubishi PLC, digital vacuum meter, temperature controller, sensors, and so on.

- Motors, valves, pneumatic valves, and meters, are all connected, the working condition can be controlled and indicated on the screen,

- Resin level alarm, over pressure alarm, valve alarm, motor alarm, wrong operating alarm, etc. All issues can be indicated on the screen

- Automatic record the running time of the each process

- System can be connected by internet, with remote control, maintenance and detecting

Automated Impregnation for Enhanced Component Performance

This VPI system uses a fully automated cycle management operated by PLC control, providing precise resin impregnation for electrical components and rotating machinery. Its seamless welded chamber and customizable pressure settings make it suitable for varied industrial needs, improving insulation and durability of products. The entire operation is safe, thanks to multiple mechanical and electrical interlocks as well as accurate digital monitoring of temperature, pressure, and vacuum levels.

Customizable Features for Diverse Applications

Users can customize the resin tank capacity, heating method (electrical/steam), and heating capacity according to specific process requirements. The systems pressure and vacuum can be tailored to different resin types and component sizes, ensuring effective impregnation across a range of products. Its robust construction using mild steel or stainless steel, combined with a paint-coated or polished surface finish, guarantees longevity even in demanding industrial environments.

Efficient and Safe Operation for Industrial Use

The VPI-1600x3000 system is designed for efficiency and safety, featuring hydraulic locking doors, advanced interlocks, and digital monitoring tools. Floor-mounted installation allows for easy integration into existing production lines. With an adjustable cycle time and noise levels below 65 dB(A), the machine delivers reliable performance with operator comfort and minimal disruption to the workplace.

FAQs of VPI System Dia 1600*3000mm For Resin Vacuum Pressure Impregnation:

Q: How does the VPI System Dia 1600*3000mm carry out resin vacuum pressure impregnation?

A: The system utilizes a seamless welded vacuum chamber in which electrical components or rotating machinery are placed. Resin is introduced under vacuum (up to 0.1 mbar), followed by controlled pressure (up to 4-8 bar), ensuring deep and uniform impregnation. Fully automated PLC management controls all cycles for optimal safety and results.Q: What types of electrical components can be processed using this VPI system?

A: The VPI-1600x3000 is designed to impregnate a wide variety of electrical components and rotating machinery such as stators, rotors, transformers, and other insulation-critical parts requiring enhanced electrical and mechanical properties.Q: When should users customize the resin tank capacity and heating method?

A: Customization is recommended when different batch sizes or resin types are used. The tank capacity and heating method (electrical or steam) can be tailored before system installation to precisely match the users specific production requirements and resin specifications.Q: Where is the VPI-1600x3000 system typically installed within a facility?

A: This floor-mounted system is usually installed in manufacturing or maintenance areas where electrical components and rotating machinery are produced or serviced. Its dimensions allow for integration into standard-sized industrial floors.Q: What safety features are integrated into the VPI system?

A: Safety is ensured through mechanical and electrical interlocks on the heavy-duty flanged hydraulic locking door, as well as digital monitoring of key parameters. These measures prevent improper operation and protect both the operator and equipment.Q: How does automated cycle management benefit users during operation?

A: The automatic PLC control ensures repeatable impregnation processes with precise temperature (1C), pressure, and vacuum management. This minimizes human error, improves process efficiency, and guarantees consistent resin insulation quality for all batches.Q: What process adjustments are possible based on material and resin type?

A: Users can adjust cycle duration, pressure, vacuum level, heating method, and temperature settings through the PLC interface to accommodate the specific characteristics of different components and resins, thereby optimizing the impregnation outcome.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Kerosene Vapor Phase Drying Equipment (VPD) For Big Power Transformer

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Highgrade Alloy Steel and Stainless Steel

Accuracy : 1C

Condition : New

Surface Finish : Other , Industrial anticorrosion paint

full automatic vacuum casting machine for epoxry resin dry-type transformers

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Material : Stainless steel (SS304) and structural steel

Accuracy : 1C (temperature), Vacuum Degree 0.001 MPa

Condition : New

Surface Finish : Other , Powder coated / sandblasted, corrosionresistant

2.5*1.6*1.6m Vacuum Annealing Furnace

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : High quality stainless steel chamber, mild steel exterior

Accuracy : 1C

Condition : New

Surface Finish : Other , Powder coated exterior, polished inner chamber

Epoxy Resin Casting Molds For Dry Type Transformer Use

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Highgrade Steel and Silicone Rubber

Accuracy : 2C

Condition : New

Surface Finish : Other , Smooth, Mirrorpolished

Send Inquiry

Send Inquiry